How Thick Should Glass Be for a Staircase? (A Practical Buyer Guide)

Glass staircases and glass balustrades bring a dramatic sense of space, light, and modern elegance to both residential and commercial interiors. But beyond their aesthetic appeal, the thickness of the glass used in stair components — whether for treads, balustrades, or guards — is one of the most critical decisions you’ll make as a buyer, designer, or homeowner.

Choosing the right thickness impacts safety, structural performance, code compliance, budget, and long-term durability. This practical guide breaks down industry standards, real-world examples, building code insights, and actionable recommendations to help you make the right choice.

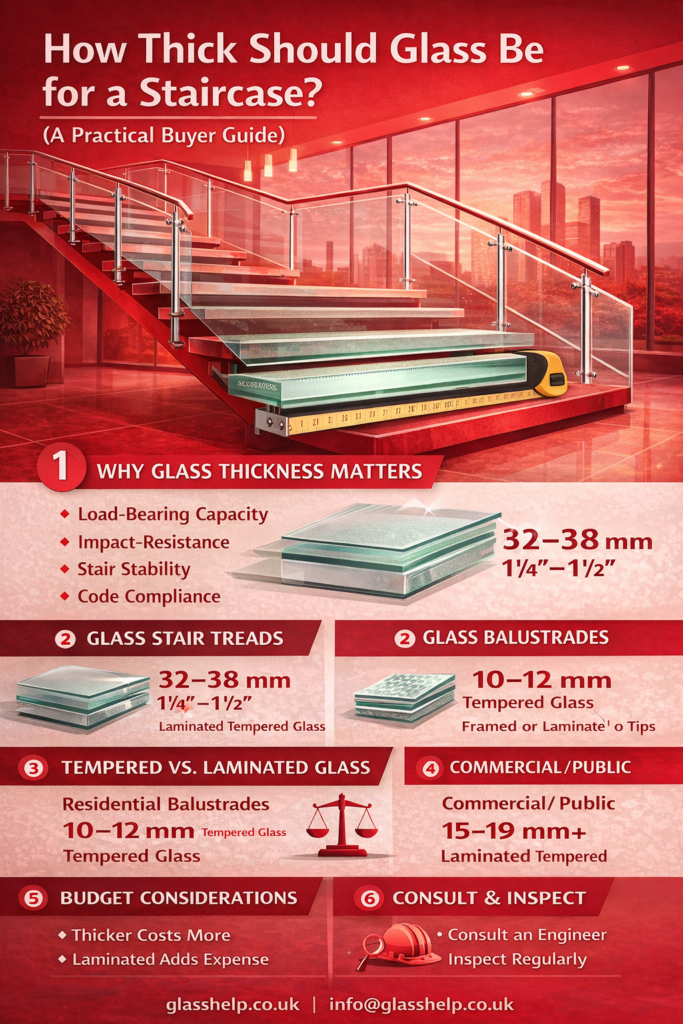

1. Why Glass Thickness Matters

Glass isn’t just transparent decoration — it carries people’s weight, resists impacts, and must meet structural and legal requirements. The thickness of glass directly affects:

- Load-bearing capacity

- Impact resistance and fracture behavior

- Stability under foot traffic or lateral loads

- Compliance with safety standards and building codes

For example, glass stair treads must carry live loads safely without cracking. Likewise, glass balustrades must withstand lateral force from leaning or accidental impact. Insufficient thickness increases risk, while excessive thickness drives cost and may require heavier supporting hardware.

2. Standard Thicknesses for Glass Stair Components

There’s no universal single thickness — it varies depending on the part of the staircase and how the glass is used. Below are common real-world benchmarks backed by industry sources.

🔹 Glass Stair Treads

Glass stair treads — the horizontal surfaces you walk on — require the greatest thickness because they directly support body weight.

- Most engineered glass stair treads use laminated tempered glass manufactured from multiple plies.

- A common thickness range for safe, walkable glass treads is 32 mm to 38 mm (about 1¼″ to 1½″) or more, depending on span and support method. GlassWalk+1

- Lamination ensures that if the glass cracks, shards remain bonded to the interlayer instead of falling away — a critical safety feature. Wikipedia

Because stair treads bear full foot traffic and often have spans without center supports, this thickness combines strength with controlled elasticity to resist cracking under impact.

🔹 Glass Balustrades & Guard Panels

Glass balustrades (railings alongside stairs) and guard panels protect against falls. Their thickness is determined by height, span, and whether the glass is structural or supported by posts/rails.

Common thicknesses found in practice include:

- 10mm–12mm tempered glass for typical residential stair balustrades. GRT Building+1

- 12mm tempered glass is a frequently specified choice for moderate loads where posts or handrails assist support. West Wholesale

- 15mm–19mm glass for frameless or structural systems without additional framing. Favorlab Glass+1

- 17.5mm laminated glass when a continuous top rail is not used — because lamination helps hold fragments in place. Park Glass

In commercial or public areas with heavy use, thicknesses of 20mm+ are often specified to meet regulatory loads. Balconette

🔹 Comparison (Residential vs Commercial)

| Application | Typical Glass Thickness | Type |

|---|---|---|

| Residential balustrade | 10–12 mm | Tempered glass |

| Frameless balustrade | 15–19 mm | Tempered or laminated |

| Glass stair tread | 32–38 mm | Laminated tempered |

| Commercial guard | 19–25 mm+ | Laminated tempered |

These ranges balance performance, aesthetics, and safety code requirements across settings.

3. Tempered vs Laminated: Why It Matters

Glass thickness isn’t the only factor — type of glass alters how thickness performs.

🔸 Tempered Glass

Tempered (or toughened) glass is heat-strengthened, making it much more impact-resistant than ordinary float glass. If broken, it crumbles into small, relatively blunt pieces, reducing injury risk.

For balustrades, 10 mm tempered glass is often the minimum starting point for residential stairrails. Cypress railings & Gates

🔸 Laminated Glass

Laminated glass sandwiches one or several interlayers (such as PVB) between glass plies. This means if the glass breaks, fragments stay bonded, and the panel remains a barrier — crucial for treads and unframed guards.

For steps and high-stress applications, multi-layer laminated glass with total thickness often beyond 30 mm is recommended. Grand Design Stairs

4. Building Codes & Safety Standards

Different regions have building code references that indirectly influence thickness decisions by specifying overall performance requirements.

🔹 Guard & Railing Codes

Building codes (such as the International Building Code in the U.S.) set performance criteria such as:

- Guards must resist specified lateral loads

- Minimum glass panel thickness is typically ¼ inch (6.4 mm) for safety glazing, but thicker is usually required based on panel size and loading. Glass Magazine

- Handrail heights are governed separately but influence how the glass panel must perform under load. GRECO | Architectural Metal Products

Even when codes specify minimums, engineers often require heavier glass to satisfy both strength and deflection limits in real installations.

5. How to Choose the Right Thickness — Practical Steps

Here’s a simple process to help you decide:

🔹 Step 1: Identify the Component

Are you specifying:

- Stair treads?

- Balustrade panels?

- Guardrail glass?

- Frameless structural walls?

Each type has different requirements — thicker for treads, more moderate for standard railings.

🔹 Step 2: Consider Usage & Traffic

- Private residence: Moderate use — 10–12 mm glass commonly suffices for balustrades.

- Public/commercial: Higher loads demand thicker or laminated designs.

🔹 Step 3: Account for Span & Support

Wider unsupported spans require thicker glass or additional support brackets/rails to control deflection and stress.

🔹 Step 4: Consult Building Codes & an Engineer

Codes provide minimums but engineered thickness ensures safety and compliance. Always consult with a structural professional and local code authority before ordering glass.

6. Real Uses: Interior Glass Walls & Stair Integration

Glass staircases often integrate with interior elements like glass walls or partitions to create cohesive, light-filled spaces. When planning such integrated features, end-to-end coordination matters.

For example, if you’re pairing glass stair components with glass partition systems or walls — such as in open-plan offices or modern homes — consider matching thickness standards and use cases.

7. Budget Considerations: Thickness vs. Cost

Glass thickness influences cost significantly:

- Thicker and laminated glass: Higher material cost + heavier installation hardware

- More layers + anti-slip finishes: Adds to fabrication time and expense

- Custom shapes/curves: Demand higher skilled labor and precision

As a rule, thicker glass means increased safety and performance but also requires careful budget planning.

8. Maintenance, Inspection & Lifespan

Glass of proper thickness, once installed, requires minimal maintenance:

- Wipe with mild glass cleaner

- Inspect anchor points and fixings annually

- Check for chips or edge damage which can reduce strength

Glass doesn’t “wear out” like wood, but impact damage or corrosion at fixings can compromise long-term performance.

Conclusion

Choosing the right glass thickness for a staircase requires careful consideration of application type, loading, code requirements, and safety. As a guideline:

- Glass stair treads: Typically 32–38 mm laminated tempered glass

- Balustrades/guards: 10–12 mm or more, increasing for frameless or higher-load applications

- Commercial/Public spaces: Often 15 mm+ laminated or multi-layer systems

Beyond numbers, always rely on structural engineers and certified installers to confirm thickness based on site conditions and local codes. This ensures your glass staircase remains as stunning as it is safe.