How to Protect Tempered Glass from Scratches and Chips

Introduction

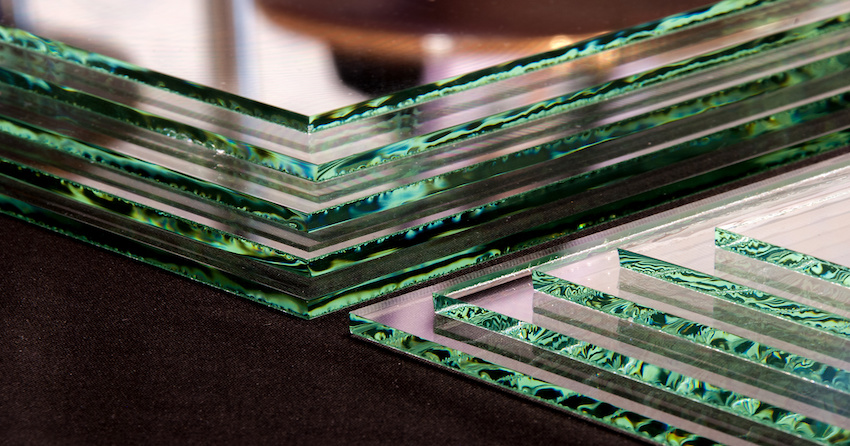

Tempered glass is a popular choice for furniture, partitions, splashbacks, and table tops because of its strength, safety, and sleek appearance. Despite its durability, tempered glass can still be scratched or chipped if not handled properly. Protecting it is essential for maintaining its aesthetic appeal and functional performance. This guide provides practical tips and strategies to safeguard tempered glass from scratches, chips, and other damage.

Why Tempered Glass Can Still Get Damaged

While tempered glass is stronger than annealed glass, it is not completely impervious to damage. Understanding the causes of scratches and chips helps in prevention:

- Abrasive materials: Sand, grit, or metal objects can scratch the surface.

- Improper handling: Dragging objects across glass or hitting it against hard surfaces.

- Edge vulnerability: The edges of tempered glass are more prone to chipping if impacted.

- Heavy impacts: Dropping heavy items or applying uneven pressure may cause chips or cracks. (GGF UK)

Cleaning and Daily Maintenance

Proper cleaning techniques reduce the risk of scratches:

- Use a soft, lint-free cloth or microfiber towel.

- Apply non-abrasive glass cleaners; avoid powders or abrasive pads.

- Clean in a circular motion, and avoid using excessive pressure.

- Remove grit or debris from the surface before wiping. (Pilkington UK)

Protective Measures for Furniture and Table Tops

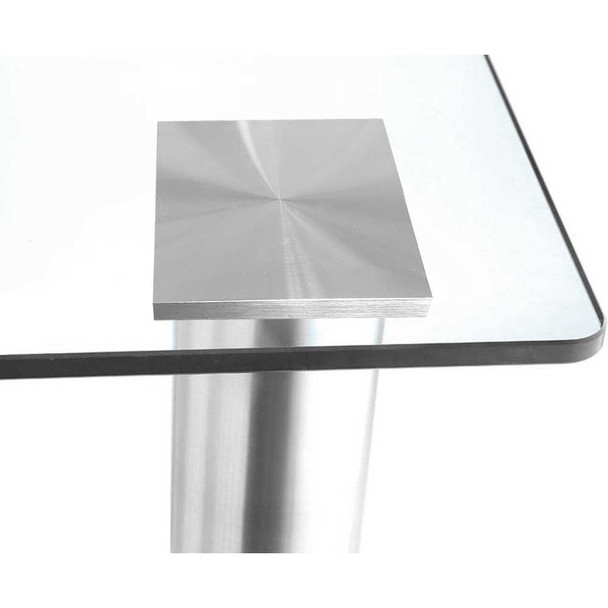

Tempered glass furniture, including desks, dining tables, and display cases, requires extra precautions:

- Use placemats or coasters: Prevent scratches from cutlery, crockery, or other items.

- Soft padding: Place felt pads or silicone bumpers under objects to avoid surface contact.

- Avoid sliding objects: Lift items rather than dragging them across the glass surface.

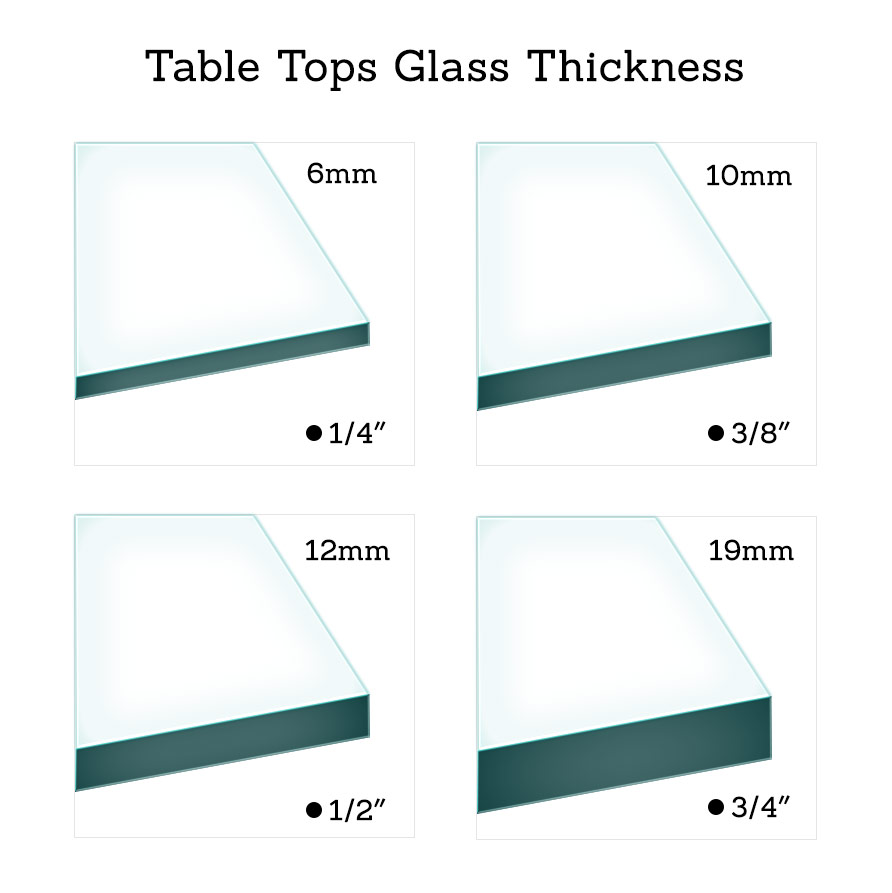

- Consider tempered Glass Table Top with rounded or polished edges to reduce chipping risks.

Edge and Corner Protection

The edges of tempered glass are more susceptible to chipping than the centre. Protection methods include:

- Installing rubber or silicone edge guards on furniture panels.

- Ensuring panels are installed with frames or channels to provide support.

- Using tempered glass with bevelled or polished edges, which reduces vulnerability. (Huxley & Co)

Preventing Damage During Installation

Proper installation is critical for long-term protection:

- Always handle panels with gloves and avoid contact with hard surfaces.

- Transport glass vertically to reduce stress on the edges.

- Ensure frames and brackets fit accurately; misalignment can create pressure points.

- Work with certified installers to meet UK building safety standards. (Gov.uk Safety Glazing Regulations)

Protective Films and Coatings

Additional protection can be applied through specialised films and coatings:

- Tempered glass films: Clear or anti-glare films can prevent scratches and add UV protection.

- Surface coatings: Hydrophobic or oleophobic coatings repel water and grease, reducing cleaning damage.

- Decorative laminates: For high-traffic areas, consider frosted or satin finishes. See Frosted Glass and Satin Glass for options.

Regular Inspections and Repairs

- Inspect tempered glass periodically for minor chips or scratches.

- Small chips on edges can sometimes be smoothed by professionals using polishing techniques.

- Replace damaged panels promptly; even minor chips can grow under stress and compromise safety. (Everest UK)

Practical Tips for Commercial Applications

Offices, restaurants, and hotels have high-traffic environments that require extra care:

- Install protective barriers or railings for glass panels near walkways.

- Use laminated tempered glass for areas prone to impact.

- Apply protective mats under furniture in dining or conference areas.

- Ensure staff are trained to handle glass safely, particularly for cleaning and moving items.

Conclusion

Protecting tempered glass from scratches and chips is crucial to preserve both its appearance and safety. Using soft cleaning materials, protective films, edge guards, and careful handling ensures longevity in both residential and commercial applications. For high-quality, durable panels, explore our range of Glass Table Top solutions along with Tempered Glass, Clear Glass, Frosted Glass, and Satin Glass.

Meta Information

Meta Title: How to Protect Tempered Glass from Scratches and Chips

Meta Description: Learn practical tips to safeguard tempered glass from scratches and chips for furniture, kitchen surfaces, and commercial applications.

Target Keywords: protect tempered glass, tempered glass scratches, tempered glass chips, tempered glass maintenance

FAQ

- Q: Can tempered glass scratch easily?

A: While more durable than regular glass, tempered glass can scratch from abrasive materials or improper handling. (GGF UK) - Q: How can I protect edges of tempered glass?

A: Use rubber or silicone edge guards, and choose panels with polished or bevelled edges. (Huxley & Co) - Q: Are protective films worth applying?

A: Yes. Films reduce scratches, protect against UV, and can enhance appearance. - Q: How should I clean tempered glass to avoid scratches?

A: Use soft, lint-free cloths and non-abrasive cleaners. Remove debris before wiping. (Pilkington UK) - Q: Can tempered glass chips be repaired?

A: Minor edge chips can sometimes be polished by professionals, but significant damage requires panel replacement. (Everest UK)