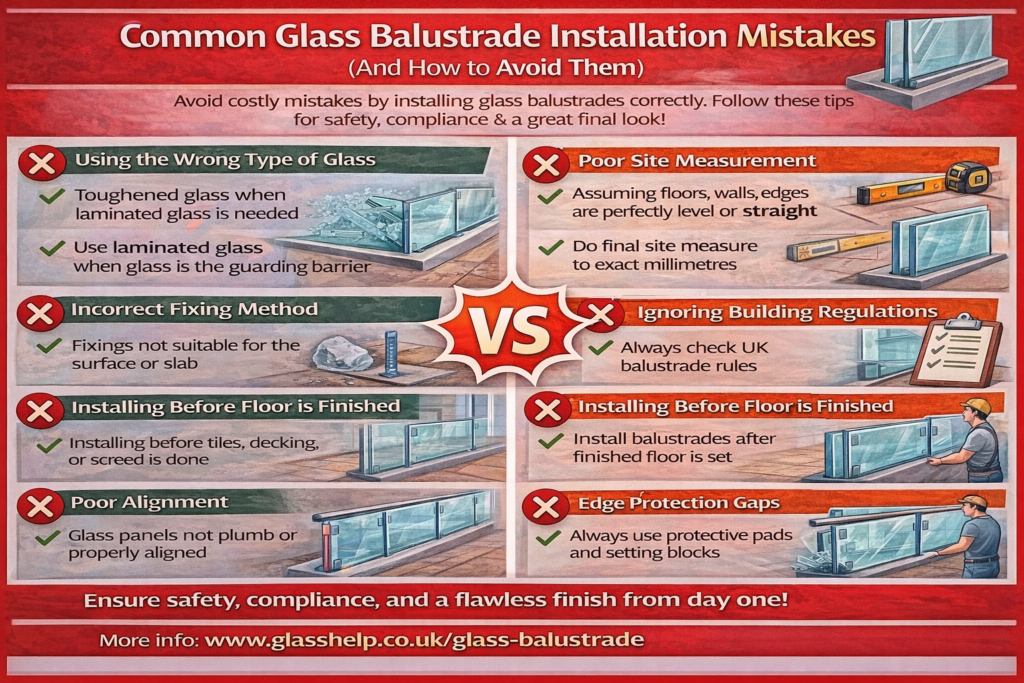

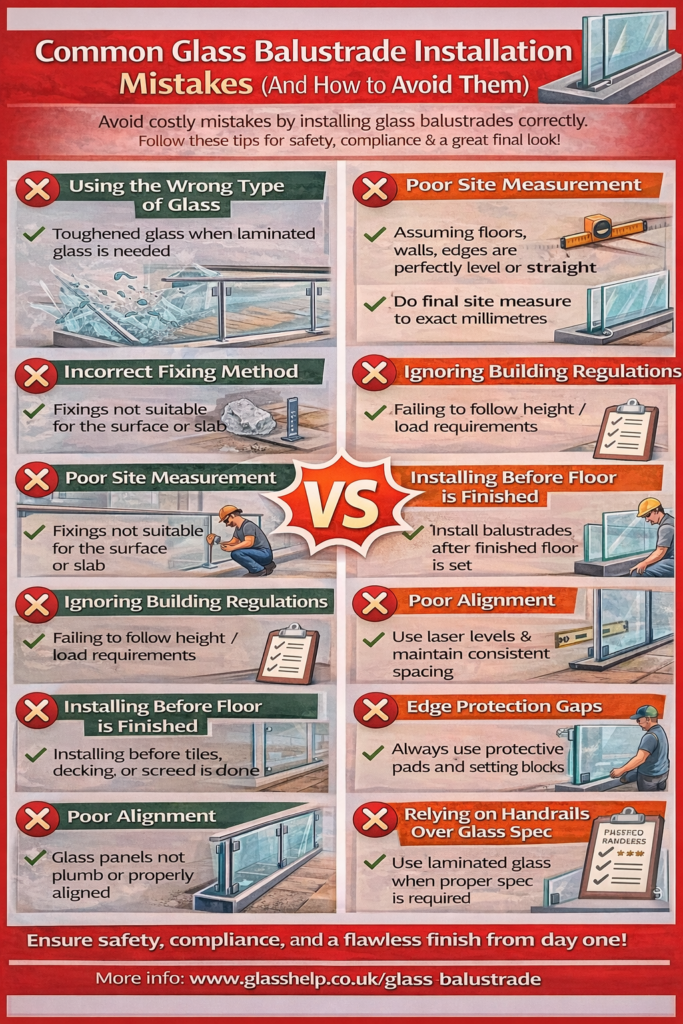

Common Glass Balustrade Installation Mistakes (And How to Avoid Them)

Glass balustrades can dramatically transform a home — opening up views, increasing light, and adding a clean, modern feel. But while the finished result often looks simple, installing a glass balustrade correctly is not.

In the UK, many problems with glass balustrades don’t come from poor materials — they come from installation mistakes. These errors can lead to:

- safety risks

- failed building inspections

- costly rework

- premature wear or movement

- glass breakage or compliance issues

This guide highlights the most common glass balustrade installation mistakes homeowners encounter — and explains exactly how to avoid them before they become expensive problems.

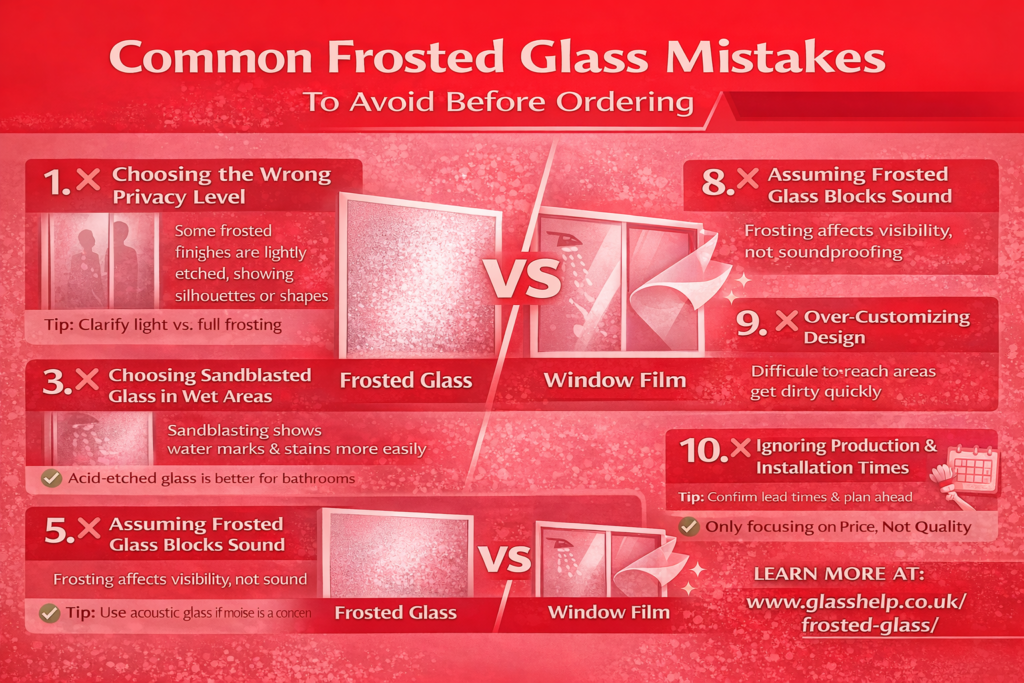

1. Using the Wrong Type of Glass

❌ The Mistake

One of the most serious and common errors is using toughened glass where laminated glass is required.

This often happens when installers or suppliers:

- cut costs

- misunderstand where laminated glass is mandatory

- assume all “safety glass” is interchangeable

❗ Why This Is a Problem

If toughened glass breaks, it shatters completely and falls away, leaving an unprotected opening. In many balustrade designs — especially frameless systems — this creates an immediate fall hazard.

✅ How to Avoid It

- Use laminated glass whenever the glass is the primary guarding element

- Always specify laminated glass for:

- frameless balustrades

- balconies

- terraces

- raised decks

- Confirm the glass specification in writing before manufacture

If you’re unsure which systems are correctly designed for laminated glass, review compliant glass balustrade systems here.

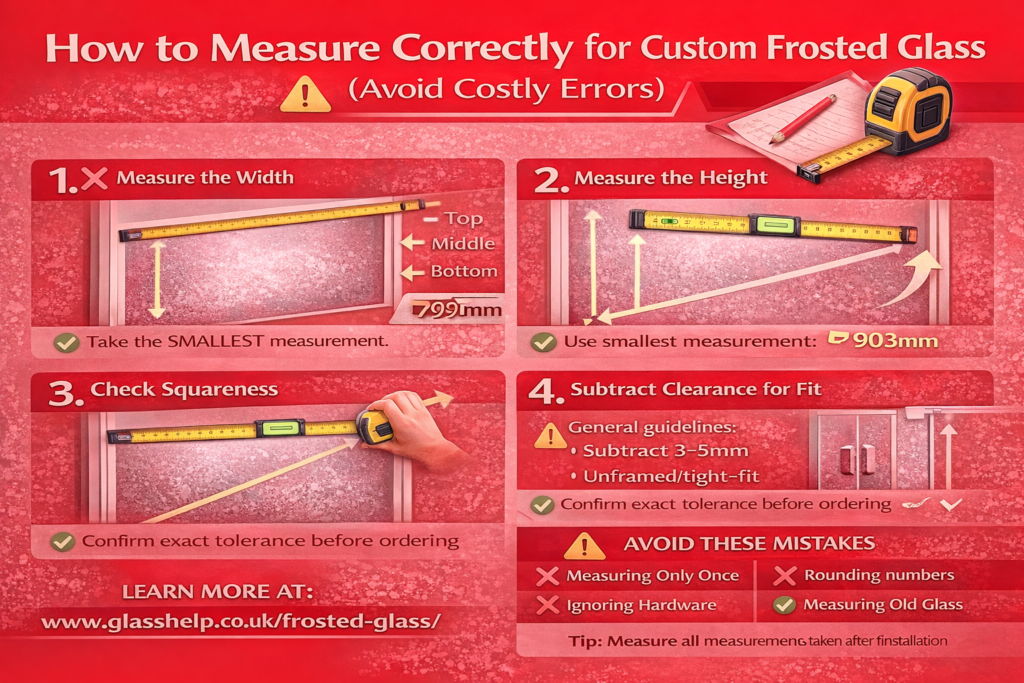

2. Poor or Inaccurate Site Measurement

❌ The Mistake

Assuming floors, walls, and edges are perfectly straight and level — especially in older UK homes.

This leads to:

- glass panels that don’t fit

- excessive gaps

- forced adjustments during installation

- compromised fixings

❗ Why This Is a Problem

Glass balustrades have very tight tolerances. Even a few millimetres of error can cause:

- misaligned panels

- stress points in the glass

- visible gaps that look unprofessional

✅ How to Avoid It

- Always carry out a final site measure after flooring and finishes are complete

- Never rely solely on architectural drawings

- Allow for tolerance in fixing systems, not in the glass itself

- Use experienced installers who measure for glass, not just general builders

3. Incorrect Fixing Method for the Surface

❌ The Mistake

Using fixings or base channels that are not suitable for the substrate, such as:

- fixing into screed instead of structural concrete

- fixing through decking without reinforcement

- inadequate edge distance near slab edges

❗ Why This Is a Problem

Glass balustrades are subject to horizontal loads, not just vertical weight. Weak fixings can lead to:

- movement over time

- loose balustrades

- failure under load

✅ How to Avoid It

- Confirm the structural makeup of the floor or slab

- Ensure fixings anchor into structural material, not finishes

- Use base channels or fixings designed for the specific surface

- If unsure, get structural advice before drilling

4. Ignoring Building Regulation Requirements

❌ The Mistake

Installing a glass balustrade without considering:

- minimum height requirements

- load resistance

- guarding rules for drops in level

This often happens with DIY installs or when copying designs seen online that aren’t UK-compliant.

❗ Why This Is a Problem

A non-compliant balustrade can:

- fail building control inspection

- delay completion certificates

- require full removal and replacement

✅ How to Avoid It

- Check balustrade height requirements early

- Ensure the system is designed to resist required loads

- Confirm whether a handrail is needed for your situation

- Work with suppliers familiar with UK regulations

5. Installing Before Floors and Finishes Are Complete

❌ The Mistake

Installing the balustrade before final floor finishes, such as:

- tiles

- decking

- screed

- waterproof membranes

❗ Why This Is a Problem

This can result in:

- incorrect balustrade height

- buried base channels

- exposed fixings

- compromised waterproofing

✅ How to Avoid It

- Install glass balustrades after finished floor levels are known

- Coordinate with flooring and waterproofing trades

- Use temporary protection if installation must happen early

6. Poor Alignment and Levelling

❌ The Mistake

Rushing installation and failing to:

- plumb panels correctly

- align multiple glass sections

- maintain consistent spacing

❗ Why This Is a Problem

Even small alignment issues become very noticeable with glass. Poor alignment:

- ruins the clean aesthetic

- creates uneven load distribution

- increases stress on fixings

✅ How to Avoid It

- Use laser levels during installation

- Dry-fit components before final tightening

- Adjust and check alignment at every stage

- Never “force” glass into position

7. Inadequate Edge Protection and Glass Handling

❌ The Mistake

Chipping or damaging glass edges during handling or installation.

This often happens when:

- glass is rested on hard surfaces

- edges contact metal fixings directly

- protective pads are not used

❗ Why This Is a Problem

Even small edge damage can:

- weaken the glass

- lead to spontaneous breakage

- invalidate warranties

✅ How to Avoid It

- Always use edge protection and setting blocks

- Never allow glass to rest directly on concrete or metal

- Keep protective packaging on glass until final positioning

8. Skipping Expansion and Drainage Considerations (Outdoor Installations)

❌ The Mistake

Ignoring:

- thermal expansion

- water drainage in base channels

- sealant compatibility

❗ Why This Is a Problem

Outdoors, trapped water and movement can cause:

- corrosion of fixings

- glass movement

- seal failure

- staining and long-term damage

✅ How to Avoid It

- Use systems designed for outdoor drainage

- Allow movement gaps where specified

- Use correct sealants compatible with glass and metal

- Avoid fully sealing drainage channels

9. Relying on Handrails Instead of Correct Glass Specification

❌ The Mistake

Assuming that adding a handrail makes any glass type acceptable.

❗ Why This Is a Problem

A handrail does not replace the need for laminated glass when:

- the glass is still the main barrier

- there are no posts below

- breakage would leave a fall risk

✅ How to Avoid It

- Treat the handrail as additional support, not primary safety

- Choose glass type based on failure behaviour, not appearance

10. Choosing Price Over Experience

❌ The Mistake

Selecting installers based purely on the cheapest quote.

❗ Why This Is a Problem

Glass balustrade installation requires:

- precision

- experience with safety glass

- understanding of regulations

Inexperienced installers may cut corners that only become visible months later.

✅ How to Avoid It

- Ask installers about previous balustrade projects

- Confirm who measures, who manufactures, and who installs

- Check warranties for both glass and installation

- Avoid “one-size-fits-all” solutions

Final Thoughts

Most glass balustrade problems are not caused by bad glass — they’re caused by avoidable installation mistakes.

By understanding these common errors and planning properly, you can ensure your balustrade is:

- safe

- compliant

- visually flawless

- long-lasting

Whether you’re installing a staircase, balcony, or terrace balustrade, starting with a correctly designed system makes all the difference. Reviewing properly engineered glass balustrade systems is the best way to avoid mistakes before installation even begins