Glass Juliet Balcony vs Traditional Railings: Pros, Cons & Visual Impact

When securing upper-floor windows or French doors, homeowners are often faced with a key design decision: glass Juliet balcony or traditional railings?

Both options provide safety, but they differ significantly in appearance, light, durability, maintenance, cost, and overall impact on your home. Choosing the wrong option can affect not only how your property looks, but also how it feels to live in.

This guide compares glass Juliet balconies and traditional railings side by side, helping you make a confident, informed decision.

Understanding the Two Options

Before comparing them, it’s important to understand what each system is designed to do.

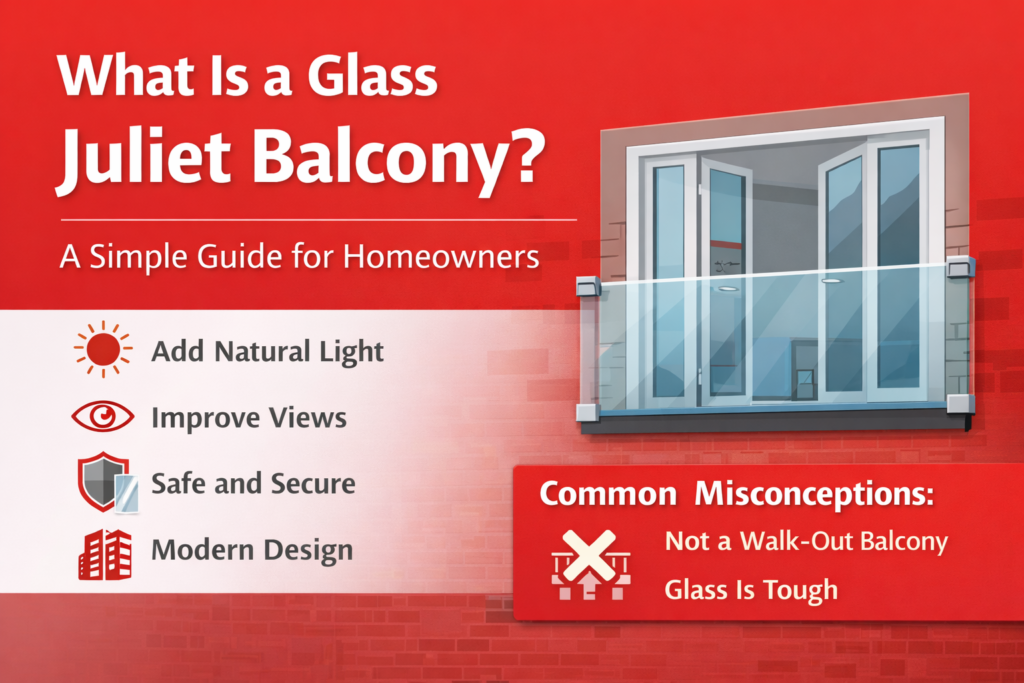

What Is a Glass Juliet Balcony?

A glass Juliet balcony is a fixed safety barrier made primarily from laminated safety glass. It is installed externally in front of full-height windows or doors, allowing them to open safely without the need for a walk-out platform.

What Are Traditional Railings?

Traditional railings are typically made from:

- Steel

- Wrought iron

- Aluminium

- Timber (less common externally)

They consist of vertical or horizontal bars designed to prevent falls while adding a more classic or utilitarian appearance.

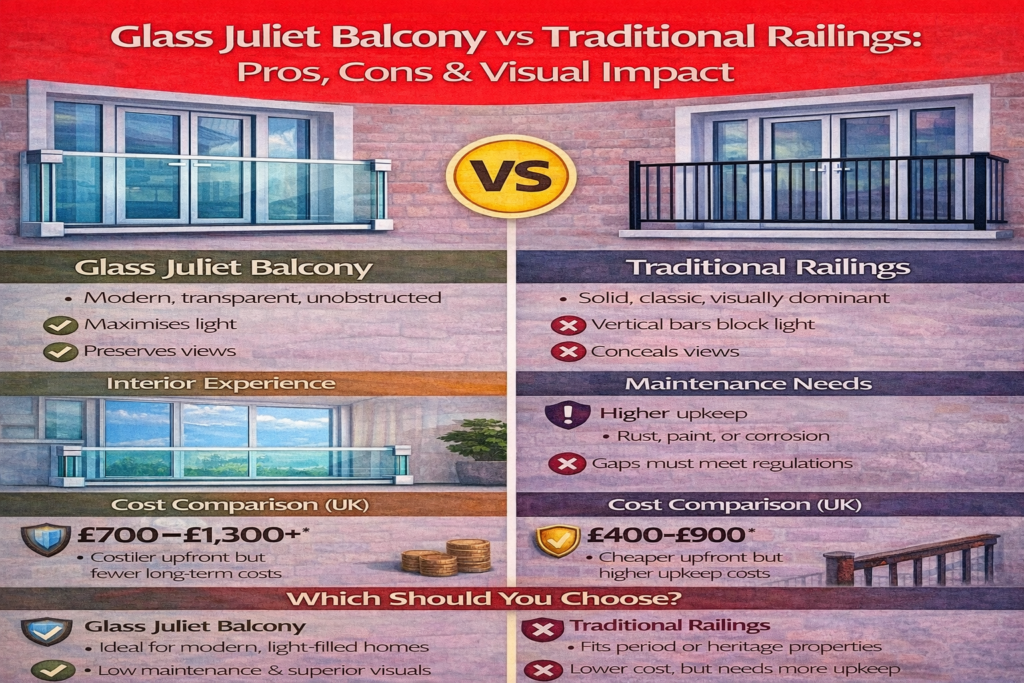

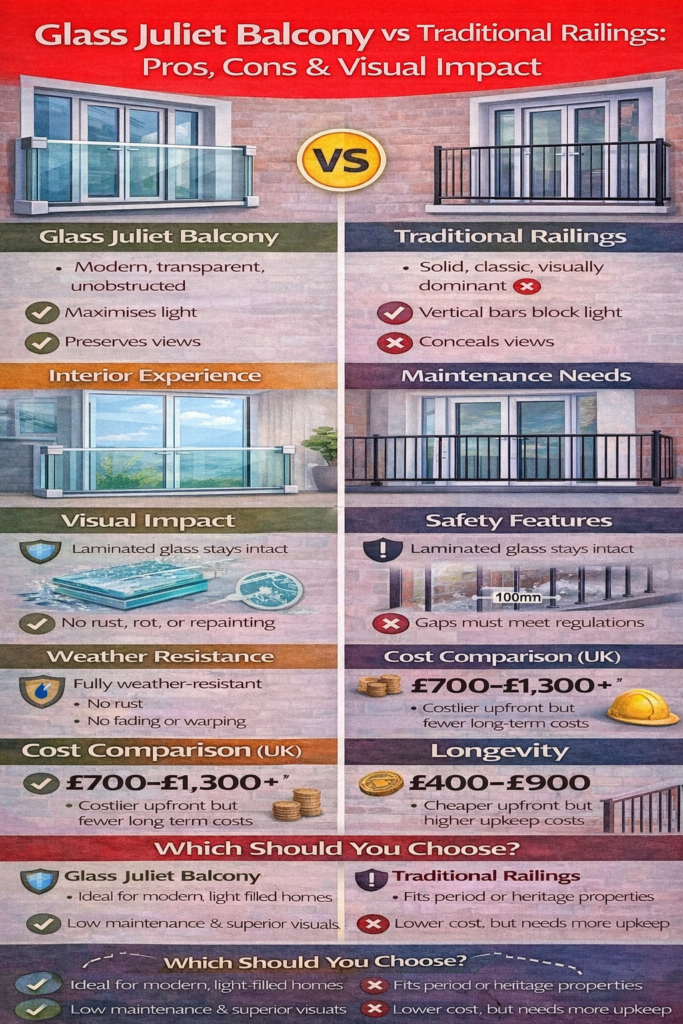

Visual Impact: Modern Transparency vs Solid Structure

Glass Juliet Balconies – Visual Advantages

- Minimal visual obstruction

- Maximises daylight into the room

- Preserves uninterrupted external views

- Creates a modern, architectural look

- Makes rooms feel larger and brighter

Glass effectively “disappears” when viewed from inside, which is one of its biggest advantages.

Traditional Railings – Visual Limitations

- Vertical bars interrupt views

- Reduce incoming natural light

- Can make interiors feel darker

- More visually dominant on the façade

While railings can suit certain architectural styles, they inevitably block sightlines.

Winner for visual impact: Glass Juliet balcony

Interior Experience: Light & Space

One of the most noticeable differences is how each option affects the interior environment.

Glass Juliet Balcony

- Allows maximum light penetration

- No shadowing from bars

- Seamless transition between indoors and outdoors

- Ideal for smaller rooms and apartments

Traditional Railings

- Bars cast shadows indoors

- Light is partially obstructed

- Can feel more enclosed

For homes where light is a priority, glass performs far better.

Safety & Performance

Glass Juliet Balcony Safety

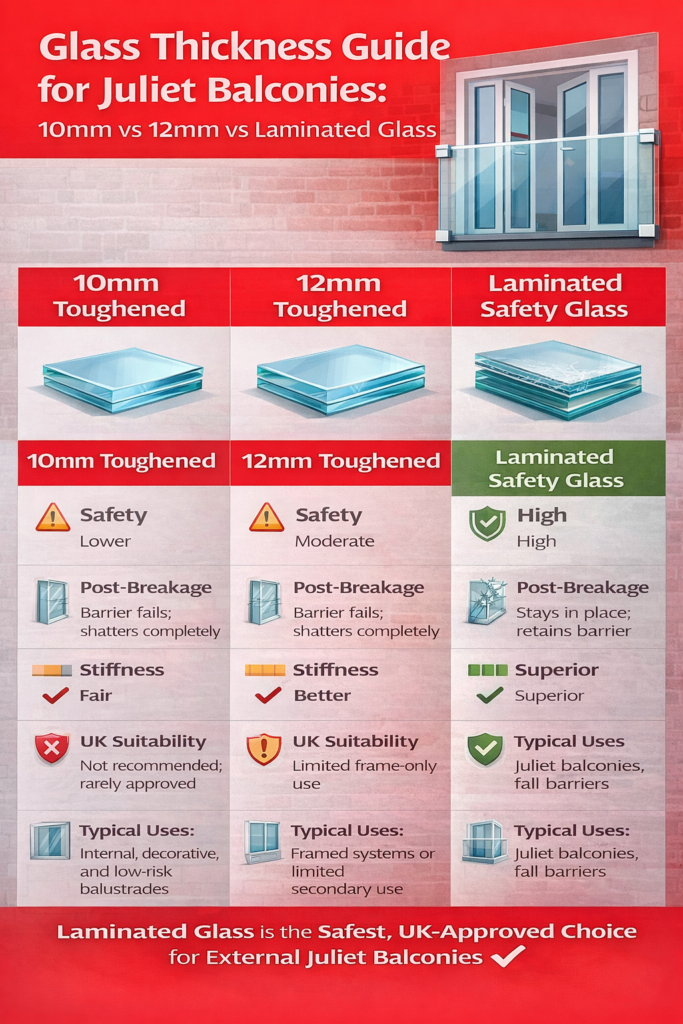

Modern glass Juliet balconies use laminated safety glass, which:

- Resists significant horizontal loads

- Holds together if cracked

- Continues acting as a barrier even if damaged

When correctly specified and installed, glass systems meet UK guarding expectations.

Traditional Railing Safety

Railings are mechanically strong and well understood. However:

- Gaps between bars must meet strict spacing rules

- Horizontal bars can be climbable (especially for children)

- Corrosion can weaken older metal railings

Both options are safe when compliant, but glass offers better post-breakage safety.

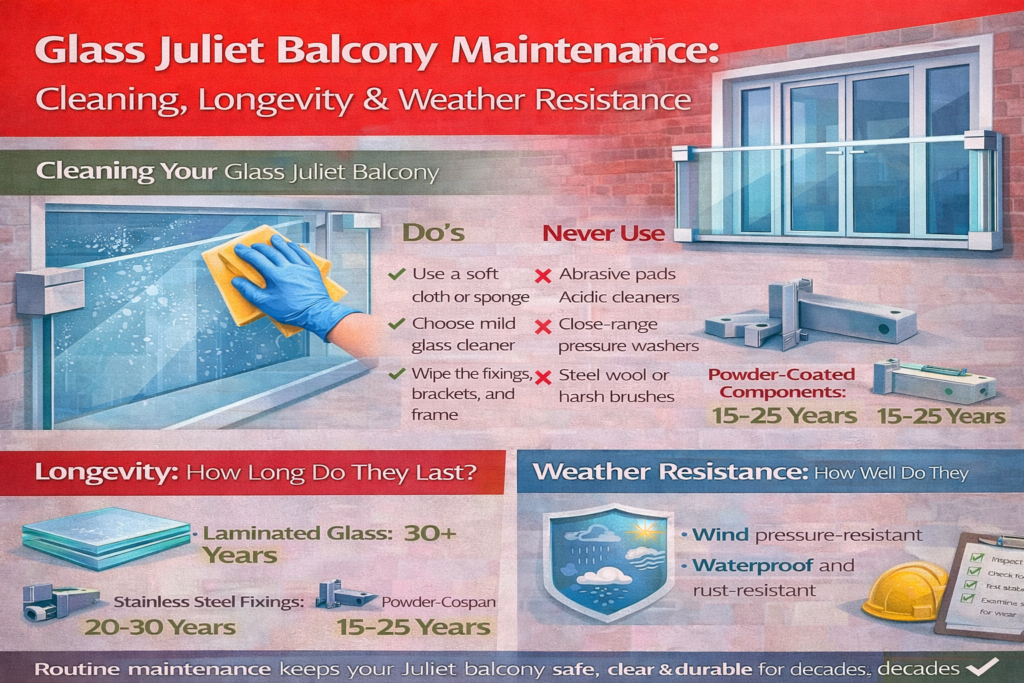

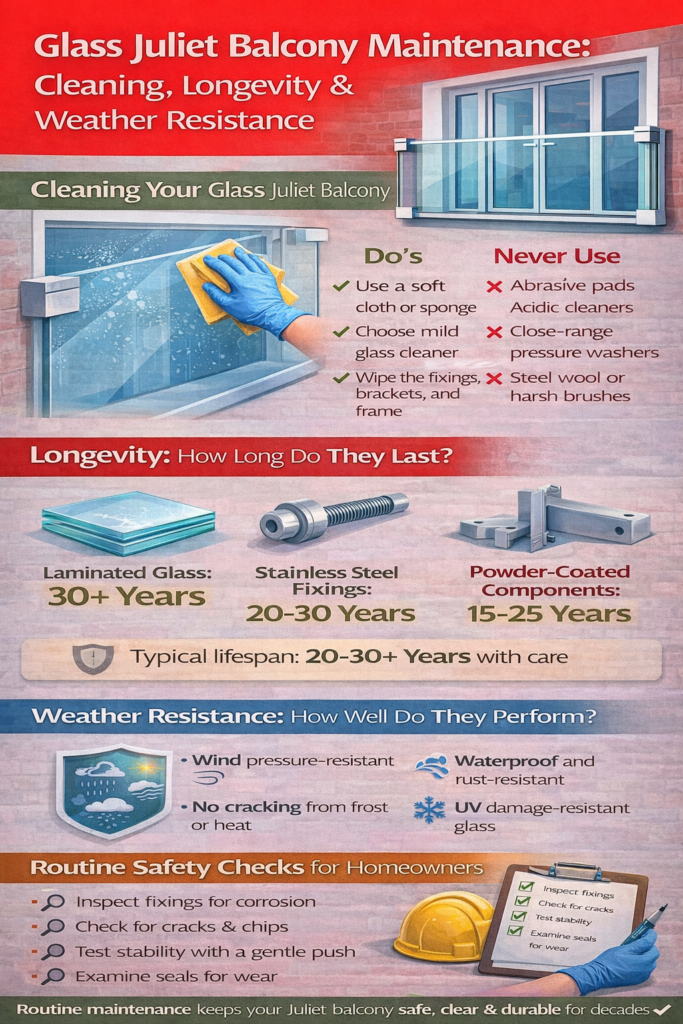

Maintenance & Longevity

Glass Juliet Balcony Maintenance

- Occasional glass cleaning

- Periodic visual check of fixings

- No repainting required

- Does not rust or rot

High-quality systems can last 20–30 years or more with minimal effort.

Traditional Railing Maintenance

- Regular painting or coating (steel / iron)

- Risk of rust or corrosion

- Timber requires sealing and treatment

- Joints and fixings may loosen over time

Maintenance costs are generally higher for railings.

Lower long-term maintenance: Glass Juliet balcony

Weather Resistance

Glass Juliet Balconies

- Resistant to rain, frost, and UV exposure

- Laminated glass does not degrade visually

- Stainless steel or aluminium fixings resist corrosion

Traditional Railings

- Vulnerable to rust in exposed or coastal areas

- Paint can peel or fade

- Timber can warp or rot

Glass systems tend to perform better in harsh UK weather conditions.

Architectural Compatibility

Where Glass Juliet Balconies Work Best

- Modern homes

- New builds

- Apartments

- Contemporary extensions

- Properties prioritising light and views

Where Traditional Railings May Suit Better

- Period properties

- Heritage-style façades

- Industrial or rustic designs

- Homes seeking a traditional aesthetic

Style matters — but so does performance.

Installation & Complexity

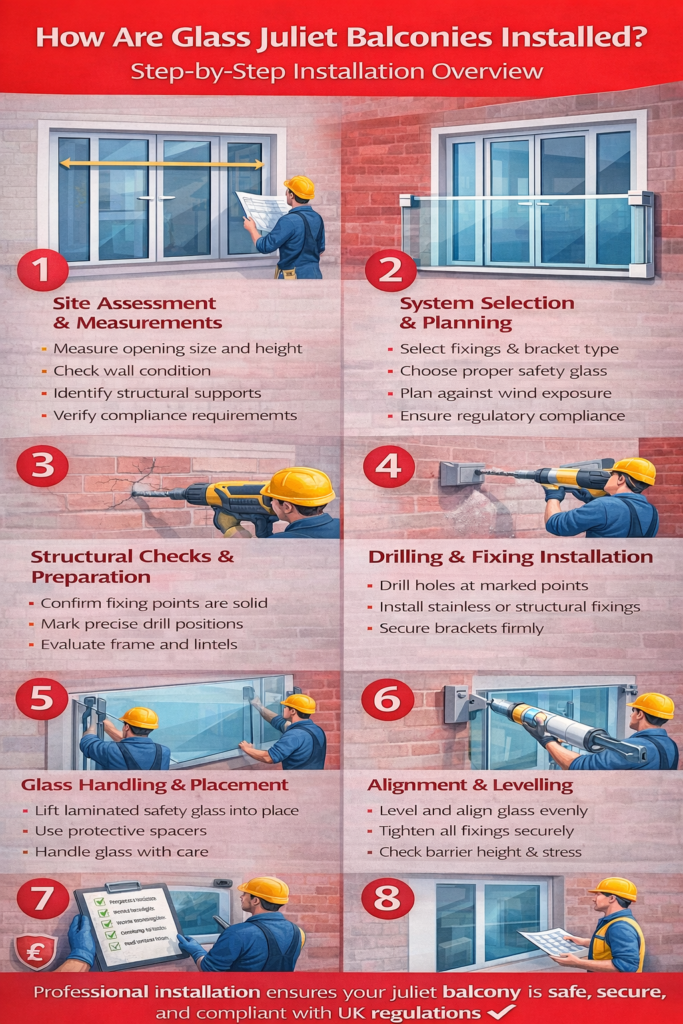

Glass Juliet Balcony Installation

- Requires precise measurement

- Professional installation recommended

- Fixings must suit wall structure

- Usually installed in a few hours

Traditional Railing Installation

- More forgiving on uneven walls

- Often simpler fabrication

- May require welding or on-site adjustments

Neither option is “DIY friendly” for upper floors, but glass systems demand greater precision.

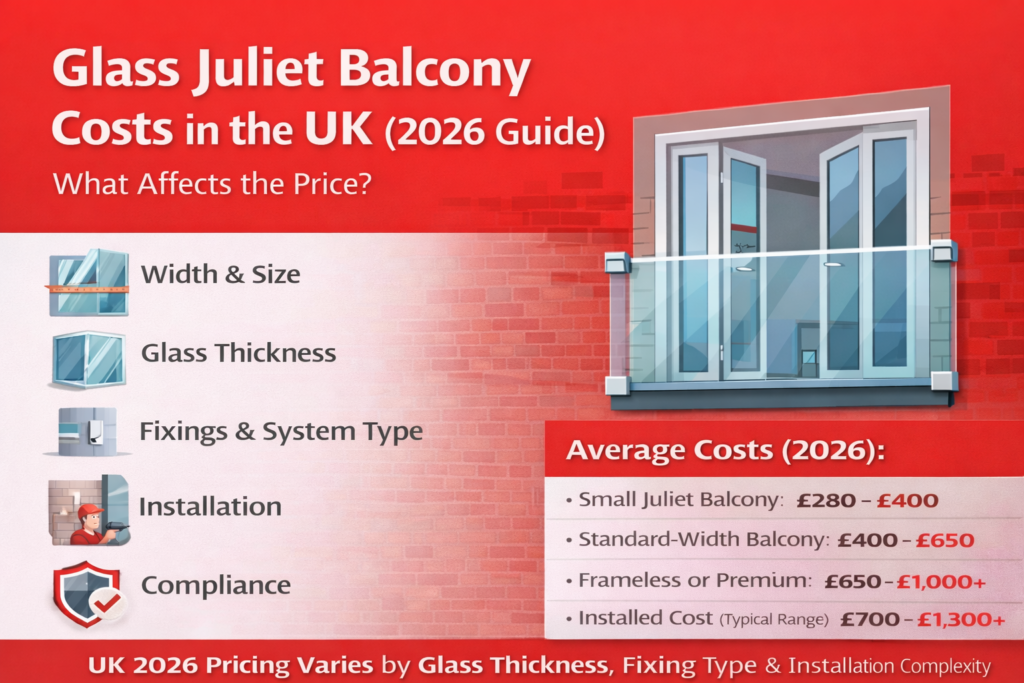

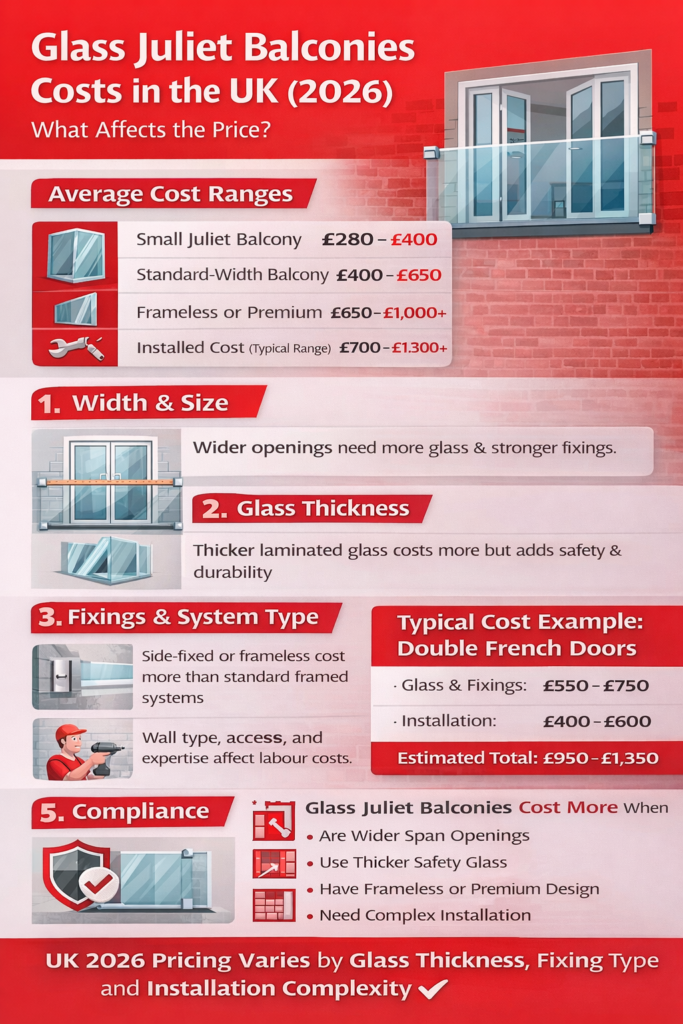

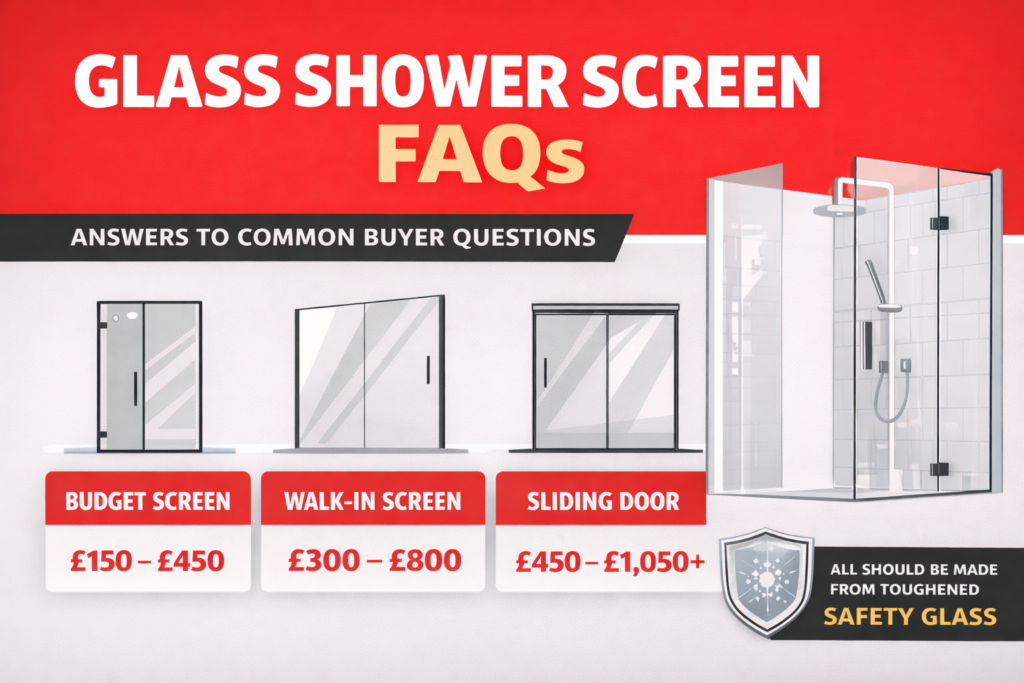

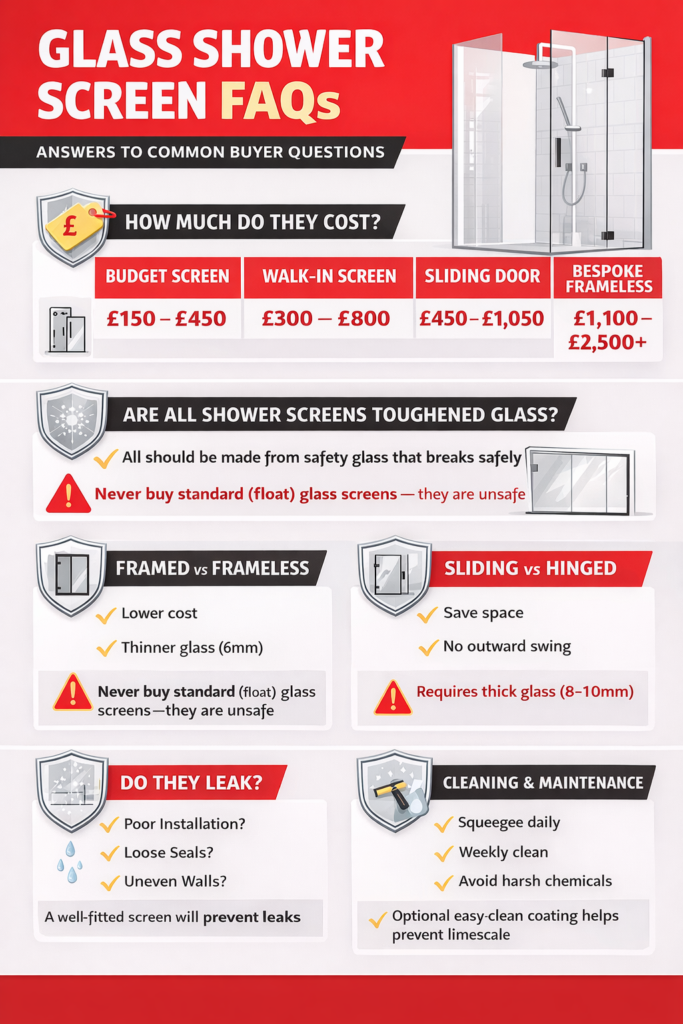

Cost Comparison (UK)

Typical Costs (Installed)

- Glass Juliet balcony: £700 – £1,300+

- Traditional railings: £400 – £900

Glass systems are usually more expensive upfront, but:

- Require less maintenance

- Age better visually

- Add more perceived value

Over time, the cost difference often narrows.

Impact on Property Value

Glass Juliet balconies are widely seen as a premium feature:

- Modern buyers favour light and openness

- Clean, contemporary appearance increases appeal

- Enhances curb appeal without bulk

Traditional railings may appeal to niche buyers but can look dated on modern properties.

Planning & Compliance Considerations

Both options generally:

- Do not require planning permission (in most cases)

- Must meet UK building regulations for guarding

Glass systems often come with clear technical specifications, while custom railings rely more heavily on installer expertise.

If you want to understand how modern glass systems are designed to meet safety expectations, this overview of glass Juliet balconies explains system design, materials, and compliance considerations clearly:

glass Juliet balconies – https://www.glasshelp.co.uk/glass-juliet-balcony/

Pros & Cons Summary

Glass Juliet Balcony – Pros

✔ Maximises light

✔ Unobstructed views

✔ Modern appearance

✔ Low maintenance

✔ Excellent long-term durability

Glass Juliet Balcony – Cons

✘ Higher upfront cost

✘ Requires precise installation

Traditional Railings – Pros

✔ Lower initial cost

✔ Classic appearance

✔ Flexible fabrication

Traditional Railings – Cons

✘ Blocks light and views

✘ Higher maintenance

✘ Can look dated

✘ Potential corrosion issues

Which One Should You Choose?

Choose a glass Juliet balcony if:

- Light and views matter most

- You want a modern, clean look

- Low maintenance is important

- Long-term value is a priority

Choose traditional railings if:

- Your property has a strong traditional style

- Budget is the primary concern

- Visual obstruction is not an issue

Expert Perspective

Many architects now favour glass solutions because they solve a safety requirement without visually dominating the building. This design-first approach aligns with modern housing trends and buyer expectations.

For an external expert overview comparing balcony guarding options, this guide offers useful context:

Balcony railing vs glass guard comparison – https://www.theglasswarehouse.co.uk/news/glass-balustrades-vs-metal-balustrades/

Final Verdict

Both glass Juliet balconies and traditional railings can provide safe fall protection — but they deliver very different experiences.

Glass Juliet balconies offer:

- Superior visual impact

- Better light performance

- Lower long-term maintenance

- Strong modern appeal

Traditional railings remain valid in specific architectural contexts, but for most modern homes, glass is the clear winner.