Shower Glass Thickness Guide: 6mm vs 8mm vs 10mm Explained

Glasshelp Guide · 2025

Read time: ~6–8 mins · Updated: 20 Sep 2025

Deciding the right thickness for your shower glass is more than just durability—it affects safety, aesthetics, cost, and the look of your bathroom overall.

In this updated guide, you’ll see what 6 mm, 8 mm, and 10 mm glass offer, with comparisons, safety norms, and tips to help you choose smartly.

Why thickness matters

Thickness impacts a few critical things in glass shower design:

- Strength & rigidity: thinner glass flexes more; thicker glass maintains shape better under use.

- Safety: tougher glass reduces risk, especially in large or frameless panels.

- Appearance & finish: thicker glass feels premium and often looks more substantial.

- Hardware requirements & cost: thicker glass needs heavier hinges, stronger fixings, more care in installation.

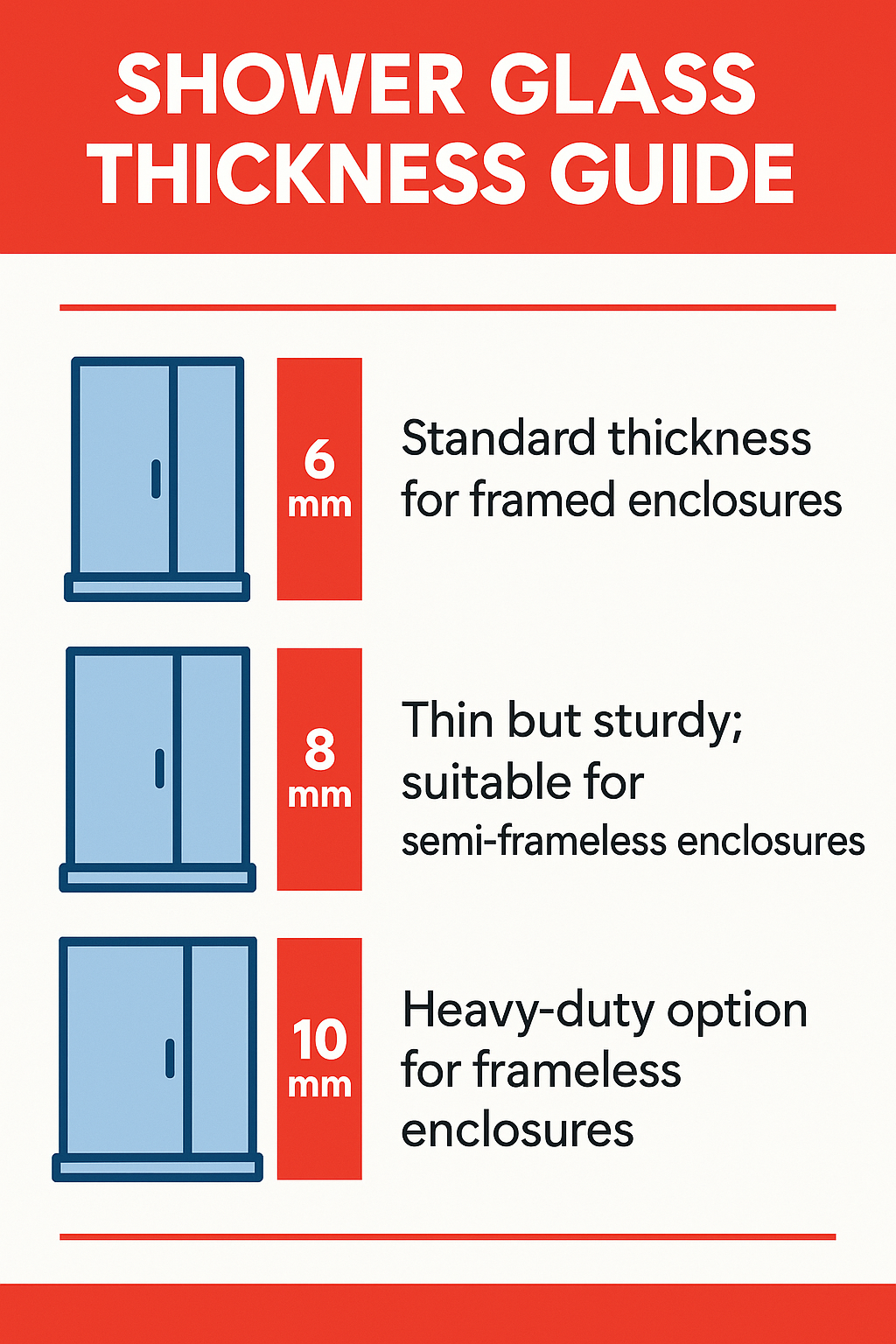

6 mm vs 8 mm vs 10 mm comparison

6 mm Glass

Pros: Lower cost, lighter panels, suitable for framed or smaller screens.

Cons: More flex, less premium feel, limited to smaller spans.

Ideal for: small shower screens, splashbacks, budget-friendly installations.

8 mm Glass

Pros: Balanced rigidity and cost; effective for frameless doors of moderate size.

Cons: Heavier, slightly more expensive, needs good hardware.

Ideal for: standard frameless shower doors, medium screens, classic wet room panels.

10 mm Glass

Pros: Maximum stiffness, high-end appearance, minimal flex in large panels.

Cons: Major cost, heavier, needs robust supports and hinges.

Ideal for: large walk-in showers, large frameless doors, luxury installations.

Which thickness for your shower setup

- If your glass width is under ~800 mm or you’re using a framed screen, 6 mm is cost-effective and safe enough.

- For frameless or semi-frameless screens of moderate width (e.g. ~800-1200 mm), 8 mm gives less flex and better durability.

- For premium walk-in showers, large panels or doors, go with 10 mm—just ensure your fittings can support the weight.

Installation, cost & safety

- Check that all fixings, hinges, and hardware are rated for the thickness you choose.

- Expect higher shipping & handling costs with thicker glass.

- Edge finishing: polished or safety-finished edges reduce risk and improve appearance (especially for exposed edges).

- Always use toughened safety glass certified to BS EN 12150 and check CE or UKCA marks. :contentReference[oaicite:0]{index=0}

- Consider spill, water spray, door movement: flex can cause strain, seal wear, leaks if glass is too thin for the span. Thicker glass helps mitigate this.

Safety standards & regulation

Here are some UK rules and expert references to help you stay compliant:

- According to GlassGuide from ToughGlaze, shower doors are often sold in 6-12 mm thickness, with 8 mm & 10 mm being very common, and all panels required to be certified to BS EN 12150. :contentReference[oaicite:1]{index=1}

- Building regulations require safety glass for glazing within 800 mm of the floor or within 300 mm of a door’s edge, and in door panels/sidelights lower than 1 500 mm from floor level. :contentReference[oaicite:2]{index=2}

- Glasstrends uses 10 mm toughened safety glass certified to BS EN 12150 and impact tested to BS EN 12600 for its frameless showers. :contentReference[oaicite:3]{index=3}

Need custom-cut shower glass?

Explore Shower Screens at GlassHelp

Frequently asked questions

Is 6 mm glass safe enough for shower doors?

For smaller or framed panels, yes—but for frameless or wide doors, 8 mm or above is usually safer and more durable. Many UK manufacturers specify BS EN 12150 toughened glass for safety. :contentReference[oaicite:4]{index=4}

Will 10 mm make a visible difference?

Absolutely for large spans—10 mm gives a more rigid, premium feel with less visual flex. But you pay more and need strong hardware. Examples from Glasstrends and ToughGlaze confirm this. :contentReference[oaicite:5]{index=5}

Does thicker glass require special maintenance?

Not really—just care with edges, seals, hinges, and using non-abrasive cleaners. No special cleaning needed beyond standard care.