Tempered Glass Myths: What People Get Wrong

Tempered glass, also known as toughened glass, is widely used in modern architecture, interior design, and home improvement projects. From shower enclosures and kitchen backsplashes to glass balustrades and office partitions, its combination of strength and safety makes it highly desirable.

Yet, despite its popularity, misconceptions and myths about tempered glass abound. Believing these myths can lead to costly mistakes, poor safety choices, or improper handling. This guide explores the most common tempered glass myths, explains what’s true and false, and provides practical advice for homeowners, designers, and builders.

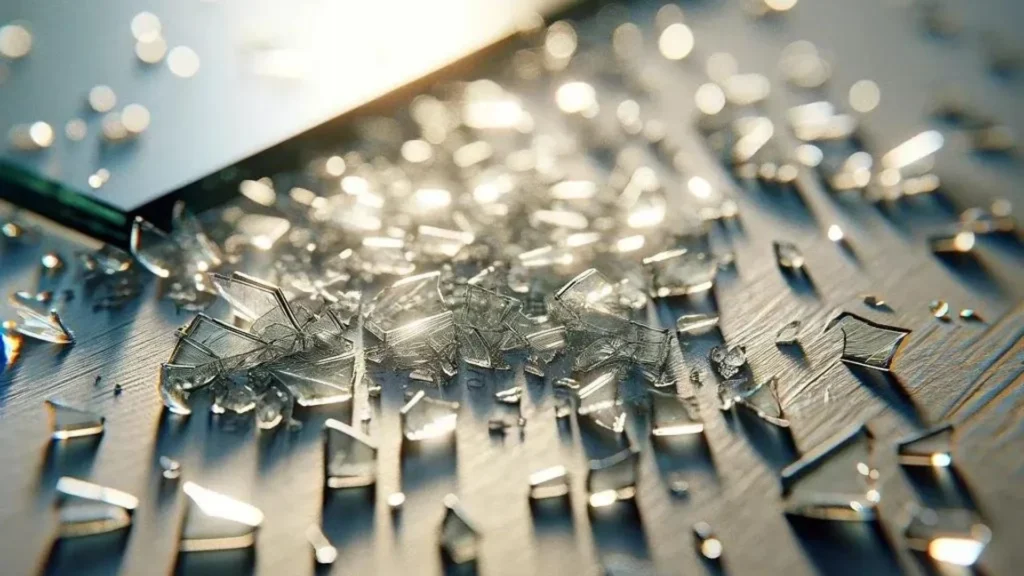

Myth 1: Tempered Glass Is Unbreakable

Reality: Tempered glass is much stronger than regular glass, but it is not unbreakable. It can resist impacts better, but if hit hard enough — especially at the edges or corners — it will break.

The difference lies in its break pattern: tempered glass shatters into small, blunt fragments instead of sharp shards, reducing the risk of injury. This safety feature is why tempered glass is mandated in bathrooms, doors, and public areas.

Authority reference: Guardian Glass – Safety Glass Explained

Tip: Always handle tempered glass with care during installation to prevent edge damage, which is the most common point of failure.

Myth 2: Tempered Glass Cannot Scratch

Reality: Tempered glass is scratch-resistant but not scratch-proof. While it is more durable than annealed glass, it can be scratched by hard objects like keys, tools, or abrasive cleaning materials.

Preventing scratches involves:

- Using microfiber cloths for cleaning

- Avoiding steel wool or abrasive pads

- Placing protective mats or coasters under heavy objects

Learn more about caring for tempered glass: Fab Glass & Mirror – Is Tempered Glass Scratch-Resistant?

Myth 3: All Tempered Glass Is Heat-Resistant

Reality: Tempered glass is more heat-resistant than standard glass, but it is not fireproof. Typical tempered glass panels can tolerate temperature differences of up to 250°C (482°F) without breaking. However, exposure to direct flame or extremely high heat may still cause damage.

For applications like wood-burning stoves or industrial ovens, ceramic or fire-rated glass is required.

Authority reference: Huide Glass – Tempered Glass Properties

Myth 4: You Can Cut or Drill Tempered Glass After Manufacturing

Reality: Tempered glass cannot be modified after tempering. Cutting, drilling, or grinding post-tempering will cause the glass to shatter instantly. All holes, cutouts, or edge finishes must be made before the glass is tempered.

Tip: Always measure carefully and plan for any hardware, fittings, or cutouts before ordering. (GlassMirrorPro – Tempered Glass Panels)

Myth 5: Tempered Glass Is Always Thicker Than Regular Glass

Reality: While tempered glass is often used in thicker panels for structural applications, thickness varies depending on use. For example:

- Shower doors: 8–10mm

- Tabletops: 10–12mm

- Balustrades/railings: 12–19mm

Thinner tempered glass can still meet safety standards if properly engineered. Thickness should be chosen based on application, safety requirements, and local building codes. (Pilkington – Glass Thickness Guide)

Myth 6: Tempered Glass Cannot Be Used Outdoors

Reality: Tempered glass is highly suitable for outdoor applications, including:

- Glass fences

- Balustrades

- Patio enclosures

- Skylights

Its tempered nature allows it to withstand temperature fluctuations, sunlight exposure, and wind pressure far better than regular glass. Outdoor tempered glass must still be correctly installed with proper hardware to prevent impact damage. (Guardian Glass – Architectural Applications)

Myth 7: Tempered Glass Is Low Maintenance

Reality: While tempered glass is durable, it still requires regular care to maintain clarity and prevent scratches. Common maintenance mistakes include:

- Using abrasive cleaners or scouring pads

- Wiping with dirty cloths that carry grit

- Ignoring edge protection during handling

Proper cleaning with soft cloths and gentle, non-abrasive cleaners is essential for long-lasting, pristine tempered glass panels. (GlassWorld – Protecting Glass Surfaces)

Myth 8: Tempered Glass Always Meets Safety Standards

Reality: Not all tempered glass is manufactured to the same quality standards. Ensure that your tempered glass complies with local or international safety certifications like:

- ANSI Z97.1 – Safety glazing in the USA

- EN 12150 – European standard for tempered glass

- CPSC 16 CFR 1201 – Consumer product safety

Choosing certified tempered glass reduces the risk of unexpected breakage and ensures compliance for legal and insurance purposes. (Huide Glass – Tempered Glass Standards)

Tips for Ordering and Using Tempered Glass Correctly

- Measure accurately — tempered glass cannot be resized after tempering.

- Choose appropriate thickness for your application.

- Select the right finish — clear, frosted, tinted, or low-iron glass.

- Plan cutouts and hardware before ordering.

- Handle with care during installation to avoid edge damage.

- Use proper cleaning methods — microfiber cloths and non-abrasive cleaners.

For reliable, high-quality tempered glass, explore GlassMirrorPro’s tempered glass panels that are custom-cut, certified, and ready for any application.

Quick Myth-Busting Table

| Myth | Reality |

|---|---|

| Tempered glass is unbreakable | Strong but can break; shatters safely |

| Cannot scratch | Scratch-resistant, not scratch-proof |

| Heat-proof | Resistant up to ~250°C; not fireproof |

| Can cut/drill after tempering | Cannot; must cut before tempering |

| Always thicker than regular glass | Thickness depends on application |

| Not suitable outdoors | Suitable with proper installation |

| Low maintenance | Requires proper cleaning and handling |

| Always meets safety standards | Must check certification |

Conclusion

Tempered glass is strong, safe, and versatile, but misconceptions can lead to mistakes during ordering, installation, or use. By understanding the truth behind these myths, you can make informed decisions and enjoy durable, beautiful, and safe glass surfaces in your home or office.

For premium tempered glass sheets, panels, and cut-to-size solutions, visit GlassMirrorPro’s tempered glass collection for certified, high-quality products that meet both aesthetic and safety needs.