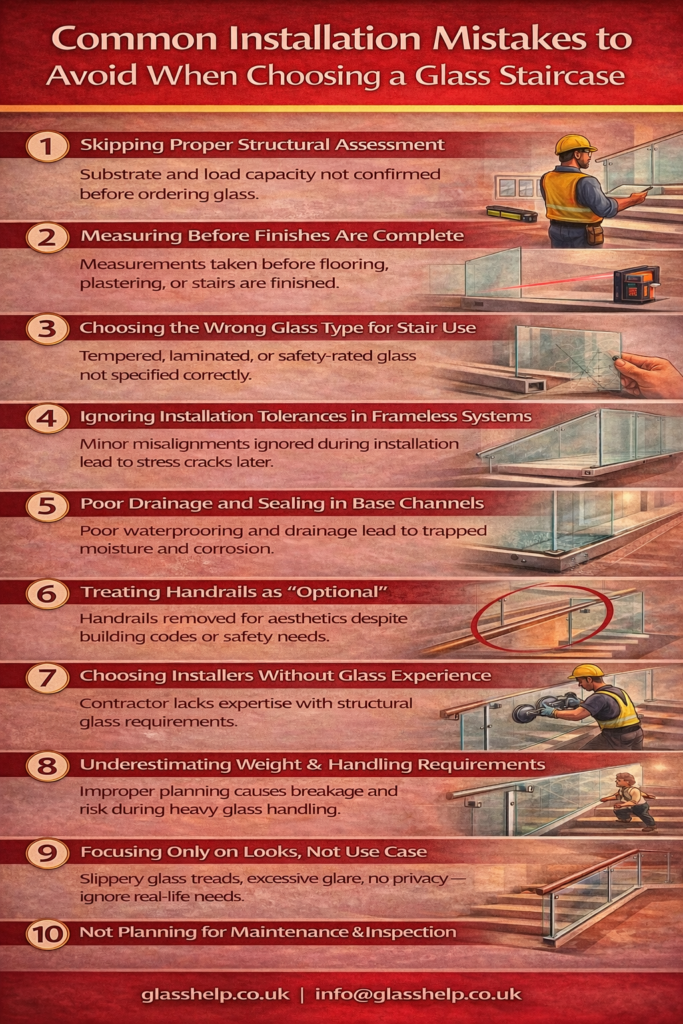

Common Installation Mistakes to Avoid When Choosing a Glass Staircase

Glass staircases can completely transform a space — adding light, openness, and a modern architectural feel. But while the finished result often looks effortless, the installation process is highly technical, and small mistakes can lead to serious safety issues, visual flaws, or costly rework.

Many problems people experience with glass staircases aren’t due to poor materials — they happen because of installation oversights, incorrect planning, or choosing the wrong system for the structure.

This guide highlights the most common installation mistakes to avoid when choosing a glass staircase, so you can make informed decisions and protect your investment from day one.

1. Skipping Proper Structural Assessment

Why this is a major mistake

Glass staircases — especially frameless designs — rely entirely on what they are fixed into. If the supporting structure is weak, uneven, or poorly prepared, even the strongest glass will fail to perform correctly.

Common issues caused:

- Glass panels leaning or deflecting

- Fixings loosening over time

- Cracking due to movement or load transfer

What should be done instead:

- Confirm whether the substrate is concrete, steel, or timber

- Ensure load paths are suitable for glass balustrades

- Get structural confirmation before ordering glass

A glass staircase should never be treated as a decorative add-on — it is a structural safety system.

2. Measuring Before Finishes Are Complete

Why this causes expensive delays

One of the most frequent (and costly) mistakes is taking final measurements before flooring, plastering, or stair finishes are completed.

Glass cannot be trimmed or adjusted on site. If measurements are off by even a few millimeters, panels may:

- Not fit into base channels

- Leave visible gaps

- Require complete re-fabrication

Best practice:

- Measure only after final finishes are installed

- Use digital laser measuring tools

- Template complex angles and stair transitions

If you want to understand why precision measuring is critical, this installation overview explains the process clearly:

👉 https://www.glasshelper.co.uk/how-glass-staircases-are-installed/

3. Choosing the Wrong Glass Type for Stair Use

Not all glass is suitable for staircases

Using the wrong type of glass is a serious safety risk. Standard annealed glass must never be used for staircases.

Common mistakes include:

- Using tempered glass where laminated is required

- Using thin glass to reduce cost

- Ignoring fall-protection requirements

Correct approach:

- Tempered glass for balustrades with secondary support

- Laminated safety glass where fall protection is critical

- Thicker glass for frameless systems

Glass staircases are governed by safety standards, not aesthetics alone.

For a deeper explanation of glass safety in stair applications, this internal guide is helpful:

👉 https://www.glasshelper.co.uk/what-type-of-glass-is-used-in-staircases/

4. Ignoring Installation Tolerances in Frameless Systems

Frameless ≠ forgiving

Frameless glass staircases look clean and minimal — but they are far less forgiving than framed systems.

Common problems:

- Visible glass lean due to uneven base channels

- Misaligned panels that can’t be adjusted later

- Stress buildup at fixings

Why it happens:

- Base channels not levelled correctly

- Substrate irregularities ignored

- Rushing the installation process

How to avoid it:

- Ensure base channels are installed and levelled first

- Allow installers time for alignment and setting

- Never “force” glass into position

Frameless systems demand precision, patience, and experience.

5. Poor Drainage and Sealing in Base Channels

A hidden long-term issue

This mistake often doesn’t show immediately — but it can cause serious long-term damage.

What goes wrong:

- Water gets trapped inside base channels

- Moisture corrodes fixings

- Glass starts to loosen or stain at the base

This is especially common near:

- Bathrooms

- Exterior doors

- Coastal or humid environments

Correct approach:

- Use base channels with drainage provisions

- Seal correctly without blocking drainage paths

- Choose corrosion-resistant hardware

Water management is just as important as structural strength.

6. Treating Handrails as “Optional”

A costly compliance mistake

Some homeowners remove handrails for aesthetic reasons — assuming glass alone is enough. In many regions, handrails are legally required, even when glass balustrades are used.

Risks of skipping handrails:

- Failing building inspections

- Reduced user safety

- Forced retrofitting later (often expensive)

Best practice:

- Confirm local building regulations early

- Use slim or recessed handrail designs if minimalism is important

- Integrate handrails into the design from the start

A well-designed handrail can enhance safety without ruining the visual appeal.

7. Choosing Installers Without Glass-Specific Experience

Glass stairs are not a general trade job

A major mistake is hiring installers who:

- Specialize in wood or metal stairs only

- Have limited experience with structural glass

- Treat glass like a decorative panel

Glass staircases require:

- Specialized handling equipment

- Knowledge of load behavior

- Experience with safety tolerances

What to check before hiring:

- Previous glass staircase projects

- Familiarity with laminated safety glass

- Understanding of alignment and base fixing systems

The right installer matters as much as the right materials.

8. Underestimating Weight and Handling Requirements

Glass is heavy — very heavy

Large glass panels and laminated treads can weigh hundreds of kilograms.

Common oversights:

- No access planning for lifting

- Inadequate manpower

- Damage during handling

Correct planning includes:

- Clear delivery routes

- Use of suction lifters and handling frames

- Adequate site access for installation day

Improper handling can cause chips, edge damage, or breakage — even before installation begins.

9. Focusing Only on Looks, Not Use Case

A design-driven mistake

A glass staircase that looks stunning in photos may not suit:

- Homes with children

- High-traffic areas

- Pets or elderly users

Examples:

- Clear glass where privacy is needed

- Slippery glass treads without anti-slip treatment

- Excessive glare from untreated glass

Smarter approach:

- Choose finishes based on how the space is used

- Add anti-slip treatments where required

- Balance transparency with practicality

Function should always guide design.

10. Not Planning for Maintenance and Inspection

Glass staircases still need care

While glass is low-maintenance, it’s not maintenance-free.

Common oversights:

- No access for cleaning inside channels

- Ignoring annual fixing inspections

- Using harsh cleaning chemicals

Best practice:

- Inspect fixings annually

- Clean using non-abrasive products

- Address chips or cracks immediately

Preventive care avoids long-term issues and keeps the staircase looking premium.

Where to Start if You’re Planning a Glass Staircase

If you’re still comparing systems, finishes, and configurations, start with a complete overview of modern glass staircase options and requirements:

👉 Glass staircase types, design options, and safety considerations

https://www.glasshelp.co.uk/glass-staircase/

This will help you align design goals with safe, installable solutions.

Final Thoughts

Most glass staircase problems aren’t caused by glass — they’re caused by poor planning, rushed installation, or incorrect assumptions.

By avoiding these common mistakes, you can ensure your staircase is:

- Safe

- Code-compliant

- Visually flawless

- Long-lasting

A glass staircase is a premium architectural feature. Treating installation as a technical process — not just a visual upgrade — is the key to getting it right.