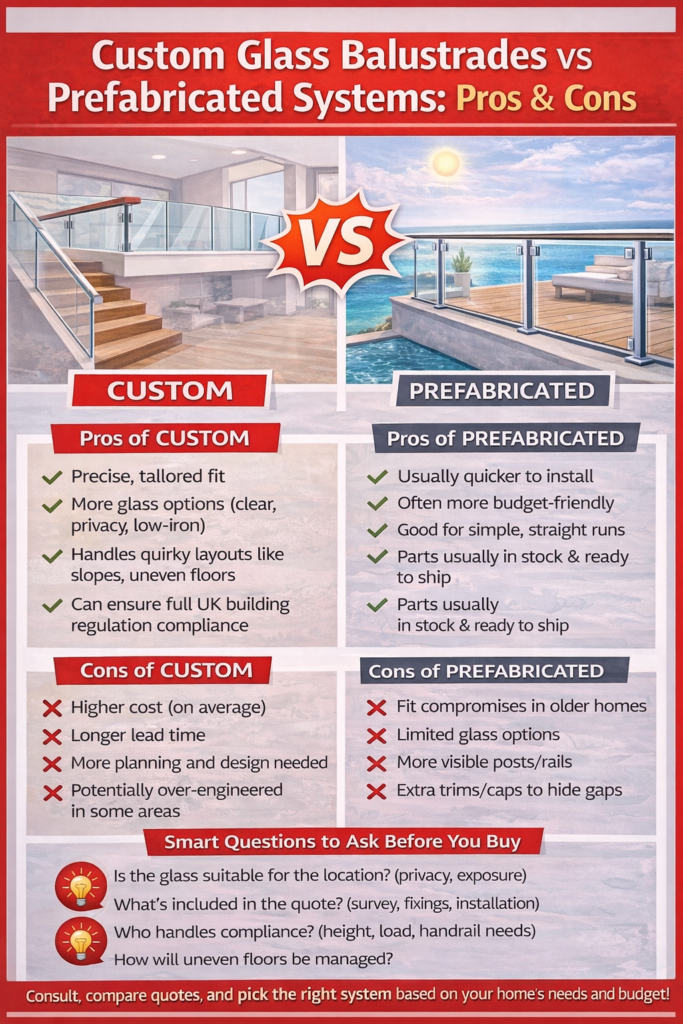

Custom Glass Balustrades vs Prefabricated Systems: Pros & Cons (UK Homeowner Guide)

If you’re planning a glass balustrade for a staircase, landing, balcony, terrace, or decking, you’ll usually face one big decision early on:

Do you go fully custom — or choose a prefabricated (off-the-shelf) system?

Both can look stunning and both can be safe — but they differ hugely in fit, finish, compliance flexibility, lead times, total cost, and long-term satisfaction. This guide breaks it all down in plain English so you can choose confidently.

1) What “Custom” and “Prefabricated” Actually Mean

Custom glass balustrade (made-to-measure)

A custom system is designed around your exact site conditions:

- exact run lengths (including awkward corners)

- precise heights, step geometry, slopes, and landings

- custom panel sizes, cut-outs/notches, and fixing positions

- glass type choices (clear, frosted, tinted, low-iron, laminated/toughened — depending on need)

It’s typically built from a measured survey and drawings, then manufactured specifically for your project.

Prefabricated (off-the-shelf / kit) balustrade system

A prefabricated system is sold as:

- standard panel sizes

- standard posts/spigots/base channel lengths

- standard handrail options

- “trim to fit” approach on site (within limits)

These can be brilliant for straightforward layouts — but can struggle when a property isn’t perfectly square, level, or predictable (which is most UK homes).

2) The Biggest Differences at a Glance

Custom is best when…

- Your space is non-standard (older homes, uneven floors, quirky stair geometry)

- You want a premium frameless look with tight sightlines and minimal hardware

- You need specific glass types (privacy, low-iron clarity, tint matching, laminated safety needs)

- You want predictable finished aesthetics (no “awkward filler pieces”)

Prefabricated is best when…

- Your layout is simple and straight

- Budget is tight and you need a fast solution

- You’re comfortable with slight compromises to fit and finish

- You’re using a contractor who installs this kit system regularly

3) Pros of Custom Glass Balustrades

✅ Perfect fit and cleaner final look

Custom panels are built for your exact measurements, so you avoid:

- odd micro-gaps

- “patch” panels at the end of a run

- awkward cuts around newel posts, stair trims, or return walls

This is where custom often looks noticeably more “architect-designed.”

✅ Freedom to choose the glass that suits the space

A major advantage is choosing glass based on real function, not just what comes in the kit.

Example: low-iron glass is popular when you want the cleanest “crystal” look (less green edge tint), especially on thicker panels. Glass Help Ltd

✅ Better for tricky compliance situations

In the UK, balustrade design must consider height, loads, and whether a handrail is needed in certain conditions. A custom approach makes it easier to engineer around real constraints and achieve a compliant design. Glass Helper+1

✅ Higher-end customisation options

Custom makes it easier to specify details that elevate the build:

- top cap vs no cap

- satin vs mirror-polished hardware

- marine-grade fixings for harsh outdoor environments

- privacy frosting or tinting for overlooked areas

- exact alignment with door frames, window mullions, or stair nosings

4) Cons of Custom Glass Balustrades

❌ Higher upfront cost (usually)

Custom typically costs more because you’re paying for:

- survey/measure

- drawings and engineering checks (as needed)

- made-to-order manufacturing

- higher precision installation

However: custom can save money if it avoids rework, returns, and “making a kit fit” for a non-standard site.

❌ Longer lead times

Because the system is manufactured after final measurements, lead times can be longer than buying a kit.

❌ More planning required

Custom is not “buy and install tomorrow.” You’ll usually go through:

- site measure

- spec choices (glass type, thickness, edges, fixings)

- manufacture

- install

5) Pros of Prefabricated (Off-the-Shelf) Systems

✅ Often cheaper for simple layouts

If your run is straight and your floor is level, kits can be a cost-effective way to get a modern glass look.

✅ Faster to purchase

You can often buy components quickly and start installation sooner.

✅ Predictable components (good for installers)

Contractors familiar with a particular kit system often install them efficiently because the parts and steps are familiar.

6) Cons of Prefabricated Systems

❌ Fit compromises are common in real homes

UK homes (especially older ones) often have:

- floors slightly out of level

- walls not perfectly straight

- stair strings that vary subtly

- corners not exactly 90°

Kits usually have tolerances — but too many “workarounds” can lead to a finish that looks less premium.

❌ Limited glass options

Many kits restrict you to what’s standard:

- standard clear toughened in fixed thickness

- fewer options for low-iron clarity, special tint matching, or privacy finishes

❌ More “visual hardware”

Some prefabricated solutions rely more on posts/rails to make the system adaptable, which can slightly reduce the clean frameless effect.

❌ Higher risk of extra parts and hidden costs

Common surprise costs with kits:

- extra posts/spigots because your run doesn’t match the standard module

- extra trims/caps to hide imperfect cuts

- more labour time because installers have to problem-solve on site

7) Safety and Compliance: The Non-Negotiables

A glass balustrade isn’t decorative — it’s a guarding system designed to prevent falls. In UK guidance, guarding is required in situations where there’s a meaningful drop, and design focuses on height, strength, and resilience. GOV.UK+1

Also, loads and design checks are commonly referenced against standards such as BS 6180 and Eurocodes (especially for public or higher-traffic settings). labc.co.uk+1

What this means for you as a homeowner:

Whether custom or prefabricated, don’t treat this like flat-pack furniture. Ensure the system is specified and installed for the real use case (indoor/outdoor, exposure, traffic levels, children/pets, etc.).

8) Which One Should You Choose? (Real-World Scenarios)

Choose custom if:

- Your staircase has turns, winders, split landings, or unusual geometry

- You want a true frameless look and tighter glass alignment

- You want premium glass like low-iron for clarity Glass Help Ltd

- You’re doing a high-value renovation and care about “architectural finish”

Choose prefabricated if:

- Your run is short, straight, and level

- You need a faster purchase and install

- You’re okay with a little extra visible hardware

- Budget is the #1 priority and you can keep the layout simple

9) Smart Questions to Ask Before You Buy (Custom or Kit)

Use these to avoid costly mistakes:

- Is the glass type right for the location? (indoor vs outdoor exposure, privacy needs, clarity expectations)

- What’s included in the quote? (survey, drawings, fixings, caps, delivery, installation, waste removal)

- What’s the warranty — and what voids it?

- How will uneven floors/walls be handled?

- Who is responsible for compliance checks?

- What’s the maintenance plan? (hardware corrosion, cleaning access, seal checks outdoors)

Final Takeaway

If you want the best fit and the most premium look, custom is usually the winner — especially in real UK homes where “standard sizes” rarely match reality perfectly.

If your project is simple, straight, and budget-driven, a prefabricated system can still look great — as long as you accept the limits and use an installer who knows the system well.

When you’re ready to explore styles, glass types, and specification options for your project, here’s the main reference page again: