Custom-Made vs Off-the-Shelf Glass Juliet Balconies: Which Is Safer?

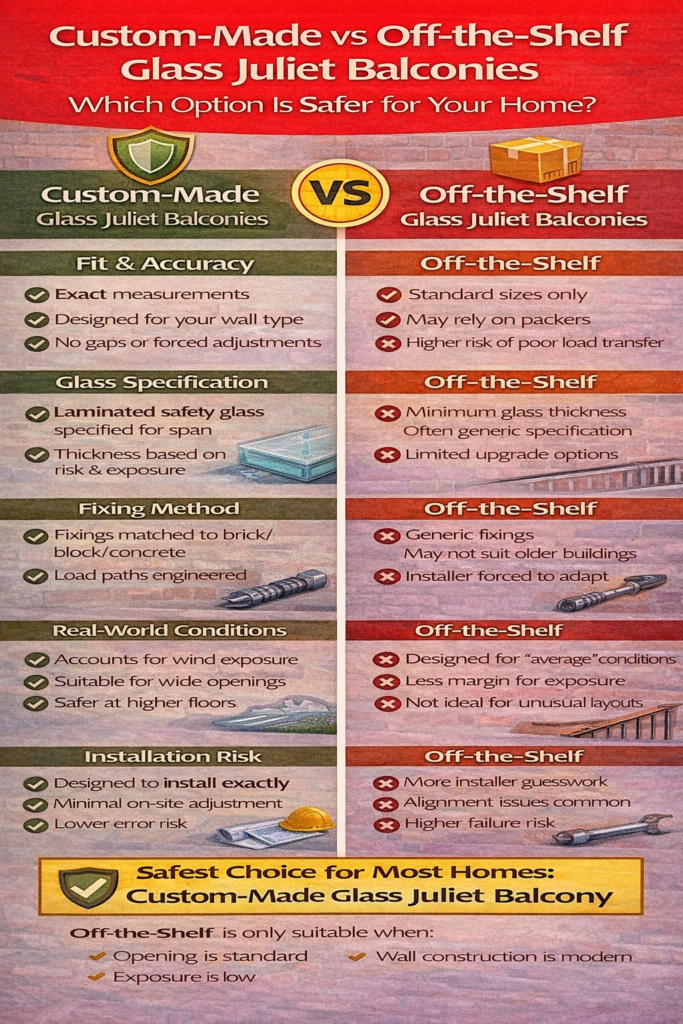

When homeowners start shopping for a glass Juliet balcony, one of the first decisions they face is whether to choose a custom-made system or an off-the-shelf (standard) option.

At first glance, both may look similar — glass panels, metal fixings, and clean lines. But when it comes to safety, compliance, long-term performance, and peace of mind, the differences can be significant.

This guide explains how custom-made and off-the-shelf glass Juliet balconies compare from a safety perspective, helping you make a confident and informed choice.

Understanding the Two Options

What Is an Off-the-Shelf Glass Juliet Balcony?

An off-the-shelf Juliet balcony is a pre-manufactured system produced in fixed sizes and configurations. These are typically sold online or through trade suppliers and are designed to fit “most” common openings.

Key characteristics:

- Standard widths and heights

- Limited fixing options

- Generic glass thickness

- Faster availability

- Lower upfront cost

They rely on the assumption that your property closely matches standard dimensions and wall construction.

What Is a Custom-Made Glass Juliet Balcony?

A custom-made Juliet balcony is designed specifically for your opening, wall structure, and exposure conditions. Measurements are taken precisely, and the system is manufactured to suit those exact requirements.

Key characteristics:

- Exact sizing

- Tailored fixing method

- Glass specification based on risk and exposure

- Greater flexibility in design

- Higher upfront cost, but greater control

Custom systems are built around performance first, rather than convenience.

Safety Starts With Fit — and Fit Is Everything

One of the biggest safety differences between the two options is how accurately the balcony fits your opening.

Off-the-Shelf Safety Risk

- Small gaps between fixings and structure

- Reliance on packers or adjustments

- Reduced load efficiency

- Greater stress on fixings

Even small mismatches can compromise how loads are transferred into the building.

Custom-Made Advantage

- Glass sized exactly to opening

- Fixings positioned optimally

- Even load distribution

- Reduced risk of movement over time

From a structural perspective, precision equals safety.

Glass Specification: Not All “Safety Glass” Is Equal

Many buyers assume that if a system uses “safety glass,” it must be safe. This is a dangerous oversimplification.

Off-the-Shelf Glass Limitations

- Often uses minimum-spec glass

- Glass thickness may not reflect exposure

- May rely on toughened glass alone

- Limited options for lamination upgrades

While these systems may pass basic requirements, they often offer little margin for real-world conditions.

Custom-Made Glass Selection

Custom systems typically specify:

- Laminated safety glass as standard

- Glass thickness matched to span and load

- Interlayers that hold glass together if broken

- Enhanced performance under impact

If safety is the priority, laminated glass specified for your exact setup is critical.

Fixing Method: The Most Overlooked Safety Factor

The fixing method is often more important than the glass itself.

Off-the-Shelf Fixings

- Designed to work in “average” walls

- Limited flexibility for unusual construction

- May not suit older brickwork or timber frames

- Often installed without structural assessment

If the fixings aren’t compatible with your wall, safety is compromised — regardless of how strong the glass is.

Custom-Made Fixings

Custom systems consider:

- Wall type (brick, block, concrete, timber)

- Fixing depth and anchor type

- Load paths and spacing

- Exposure to wind and height

This tailored approach ensures the balcony works with the building, not against it.

Real-World Loads vs Catalogue Conditions

Off-the-shelf products are tested in controlled environments, not necessarily for your property’s conditions.

What Standard Systems May Not Account For

- High wind exposure

- Elevated floors

- Coastal corrosion risk

- Non-standard wall construction

- Large door openings

Custom-made balconies factor these risks in from the start.

Building Regulations & Compliance Reality

UK building regulations focus on performance, not product labels.

Both options can comply — but compliance depends on how well the system suits the building.

If you want a clear overview of how compliant systems are designed and what factors matter most, this guide to glass Juliet balconies explains modern system design and safety expectations in detail:

glass Juliet balconies – https://www.glasshelp.co.uk/glass-juliet-balcony/

Custom-made systems generally make compliance easier to demonstrate, especially when building control asks questions.

Installation Risk: One Size Does Not Fit All

Installation errors are a leading cause of safety issues.

Off-the-Shelf Risk

- Installers forced to “make it work”

- Improvised packing and alignment

- Fixings installed in sub-optimal positions

- Greater reliance on installer judgment

Custom-Made Benefit

- Designed to install exactly as specified

- Fewer on-site adjustments

- Clear fixing instructions

- Lower risk of deviation

Reducing installer guesswork significantly improves safety outcomes.

Long-Term Safety & Durability

Safety isn’t just about day one — it’s about how the system performs 10 or 20 years later.

Off-the-Shelf Longevity Concerns

- Fixings under constant stress

- Glass edges closer to tolerance limits

- Greater chance of loosening over time

- Limited ability to replace parts

Custom-Made Longevity

- Balanced structural loads

- Reduced stress concentrations

- Better corrosion resistance options

- Easier future maintenance

Custom systems age more predictably — a key safety factor often overlooked.

Cost vs Risk: A Realistic Perspective

| Factor | Off-the-Shelf | Custom-Made |

|---|---|---|

| Initial cost | Lower | Higher |

| Fit accuracy | Variable | Exact |

| Glass safety margin | Minimal | Optimised |

| Fixing suitability | Generic | Tailored |

| Long-term safety | Moderate | High |

A lower upfront cost may feel attractive, but safety-critical features are not the place to cut corners.

When Is Off-the-Shelf Acceptable?

Off-the-shelf systems can be suitable when:

- Opening size is standard

- Wall construction is modern and known

- Exposure is low

- Height above ground is limited

- Installation is carried out by experienced professionals

Even then, careful verification is essential.

When Custom-Made Is the Safer Choice

Custom-made Juliet balconies are strongly recommended when:

- Openings are wide or unusual

- Property is older or non-standard

- Building is exposed to wind

- Safety margin is a priority

- Building control scrutiny is expected

From a safety standpoint, customisation reduces unknowns.

Expert Insight

Many structural specialists agree that Juliet balconies fail not because glass is weak, but because systems are poorly matched to buildings. Custom-made designs minimise these mismatches.

For an additional industry perspective on safety considerations and specification choices, this overview is useful:

Juliet balcony glass safety explained – https://www.theglasswarehouse.co.uk/news/is-glass-strong-enough-for-balustrades/

Final Verdict: Which Is Safer?

Custom-made glass Juliet balconies are objectively safer in most real-world situations because they:

- Fit precisely

- Use correctly specified laminated glass

- Match fixings to the structure

- Reduce installation risk

- Provide greater long-term reliability

Off-the-shelf systems can work — but only when conditions are ideal and verified.

When safety is the priority, customization is not a luxury; it’s a safeguard.