Toughened vs Heat-Strengthened Glass: What’s the Difference

Glass Knowledge · 2025

Read time: ~7 mins · Updated: 25 Sep 2025

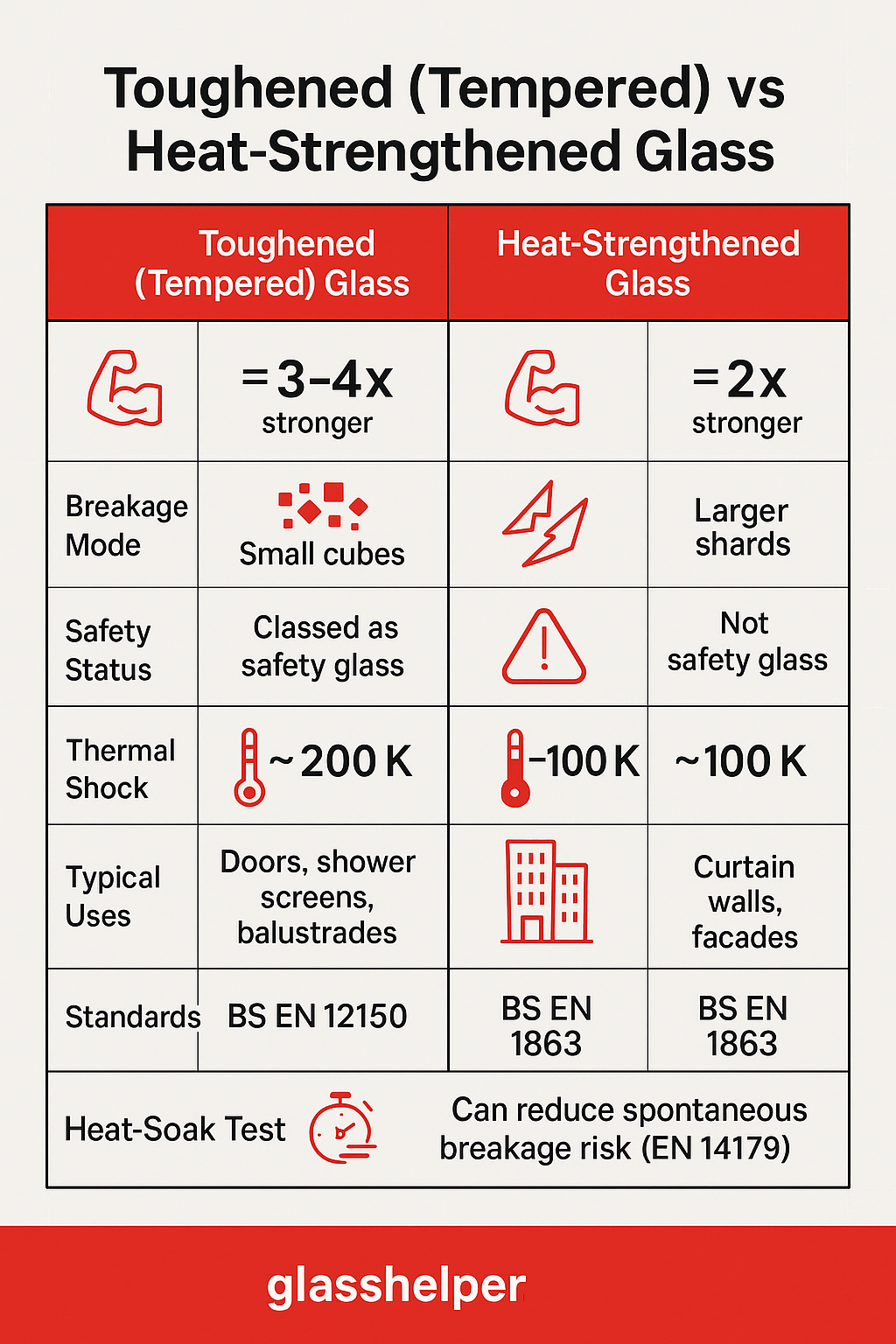

When choosing safety glass for windows, facades or interiors, two common heat-treated types come up:

toughened (tempered) and heat-strengthened.

They may sound similar but their strength, breakage pattern and safety classification are quite different.

This guide explains the key differences and where each is best used.

What is toughened (tempered) glass?

Toughened glass is standard float glass heated to ~620°C and then rapidly cooled. The rapid quench puts the outer surfaces into compression and the inner core into tension, making it significantly stronger.

- ~4–5× stronger than ordinary annealed glass.

- Breaks into small blunt granules — safer for people nearby.

- Recognised as safety glass under BS EN 12150.

- Common in doors, shower screens, balustrades, furniture and partitions.

What is heat-strengthened glass?

Heat-strengthened glass is produced in a similar way but cooled more slowly. This gives it a lower surface compression than fully toughened glass, with different performance outcomes.

- ~2× stronger than ordinary annealed glass.

- Breaks into larger shard-like pieces (not safety glass alone).

- Recognised under BS EN 1863.

- Often laminated to provide safety — suitable for curtain walls and structural glazing.

Detailed comparison

Where each type is used

- Toughened: Best for areas with human impact risk — shower enclosures, doors, balustrades, partitions.

- Heat-strengthened: Favoured in architectural glazing (curtain walls, facades) where glass is laminated and distortion must be minimized.

Learn more about tempered glass options

or explore custom cut glass solutions for your project.

References & further reading:

BSI: BS EN 12150 Toughened Glass Standard,

BSI: BS EN 1863 Heat-Strengthened Glass Standard,

ASTM C1048-21: Heat-Treated Flat Glass

Need the right safety glass for your project?

Shop Safety Glass at GlassHelp

Frequently asked questions

Is heat-strengthened glass considered safety glass?

No. Unlike toughened, it does not meet the breakage pattern requirements to be classed as safety glass unless laminated.

Which is stronger, toughened or heat-strengthened?

Toughened (tempered) glass is around 4–5× stronger than annealed, while heat-strengthened is about 2× stronger.

Why would someone choose heat-strengthened glass?

It offers lower optical distortion than toughened, making it better for laminated curtain wall glazing where aesthetics matter.

Can either type be cut after treatment?

No. Cutting, drilling or edge finishing must be done before heat treatment. Post-treatment modification will cause breakage.

Which has better thermal resistance?

Toughened glass resists temperature differences up to ~200 K, compared to ~100 K for heat-strengthened.