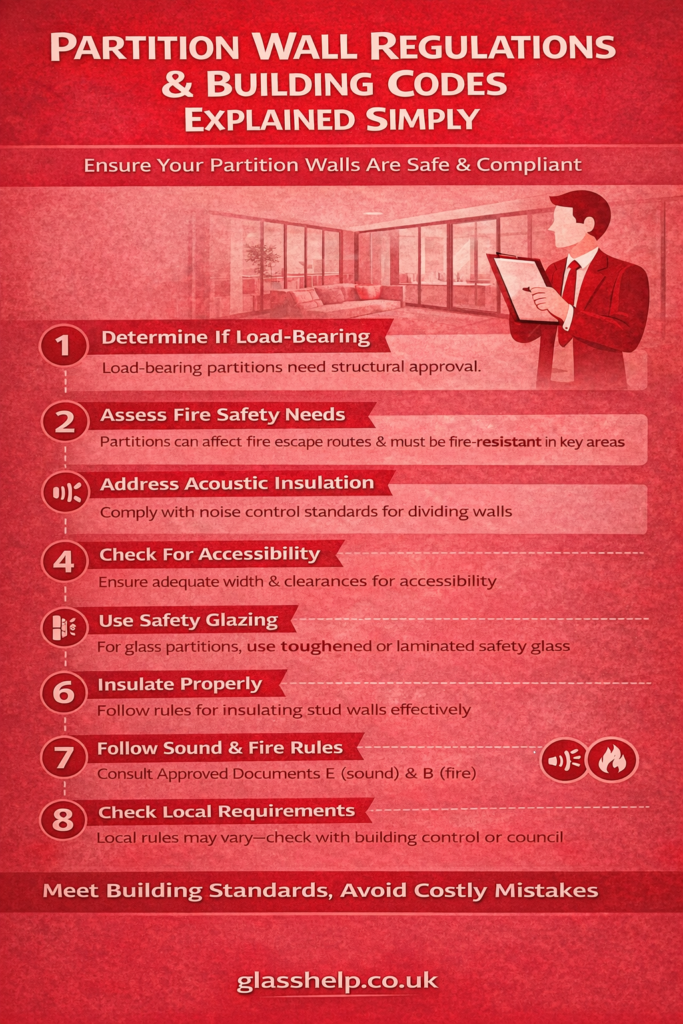

Glass Shower Screens Explained: Types, Safety Standards, and Regulations

Glass shower screens are one of the most popular features in modern bathrooms — combining style, transparency, and ease of cleaning. But beyond good looks, shower screens must meet strict safety standards and building regulations to protect users and ensure longevity.

Whether you’re renovating your bathroom or planning a new project, this comprehensive guide breaks down:

- The types of glass shower screens

- Key safety and regulatory requirements in the UK

- How thickness impacts performance and safety

- Design choices and installation considerations

What Is a Glass Shower Screen?

A glass shower screen is a fixed or hinged panel (or set of panels) that separates the showering area from the rest of the bathroom to contain water and create a protected shower enclosure.

These screens may be:

- Framed (glass held within a metal frame)

- Semi-framed (some framing with exposed edges)

- Frameless (minimal hardware for a sleek look)

Each style offers a different balance of clean aesthetic, installation method, and cost.

If you want inspiration, types, and design options before deciding which shower screen suits your space, check out this comprehensive guide to shower screens:

👉 Glass shower screens guide and design options — https://www.glasshelp.co.uk/glass-shower-screens/

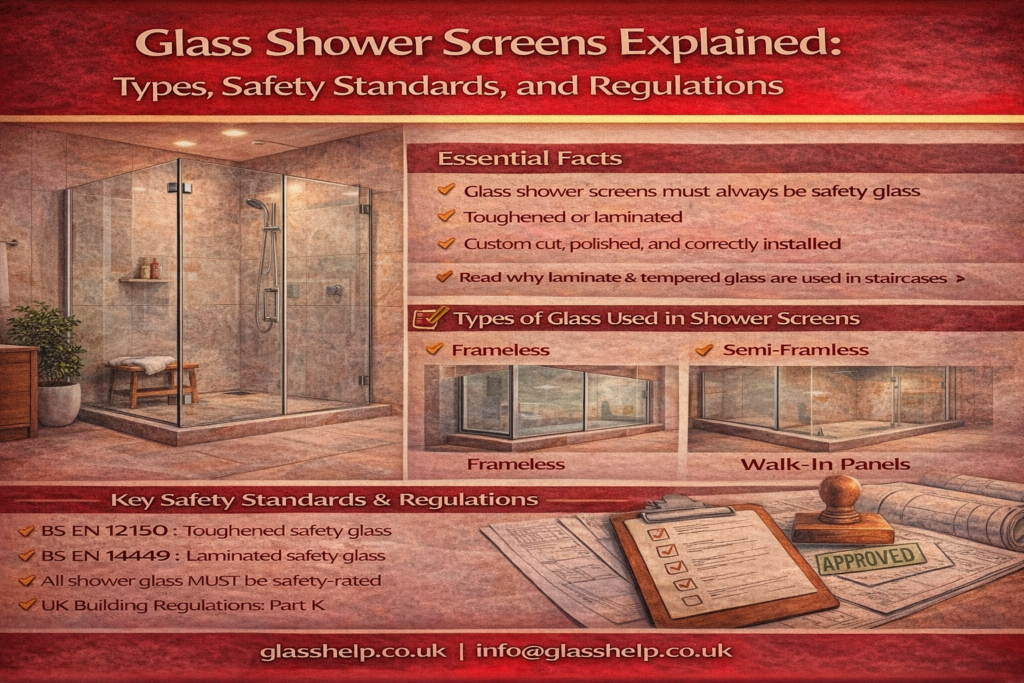

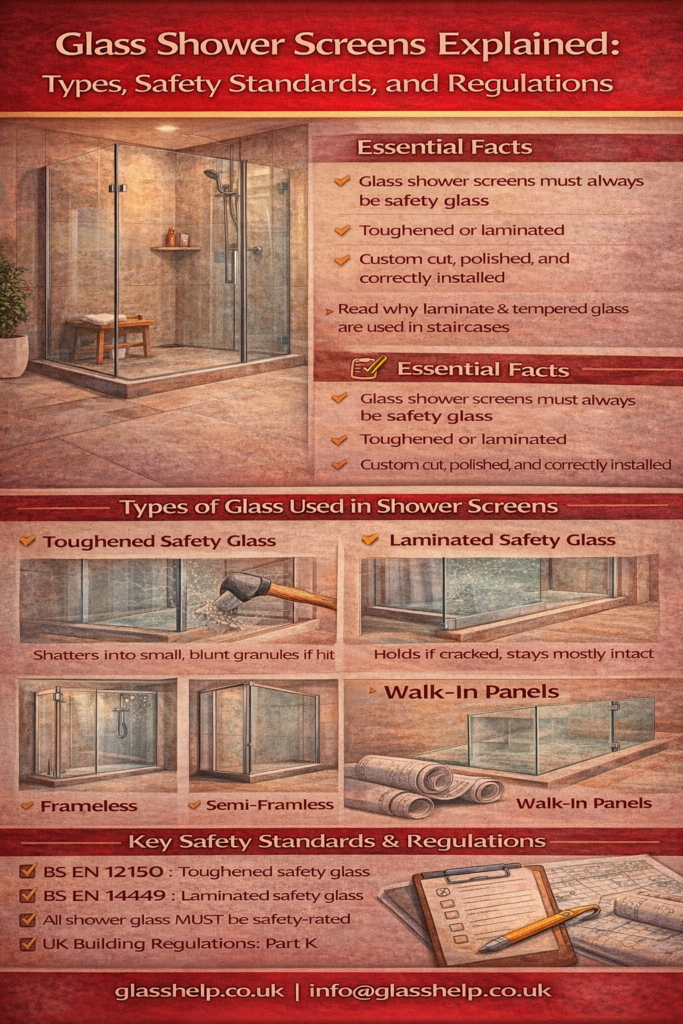

Types of Glass Used in Shower Screens

Glass shower screens are always made from safety-rated glass — not ordinary window glass. Safety glass is engineered to reduce the risk of injury if it breaks, which is essential in a wet, high-impact bathroom environment.

1. Toughened (Tempered) Glass

Toughened safety glass undergoes controlled heating and rapid cooling to create internal stresses that make it significantly stronger than regular glass. If it does break, it shatters into small, blunt granules rather than sharp shards, reducing the risk of serious injury. ToughGlaze+1

This is the most common type of glass used in shower screens — especially in frameless or semi-framed applications. Shower Glass

📌 Typical standards:

Toughened glass in the UK must comply with BS EN 12150, which covers manufacturing and impact resistance. abc Glass Processing

2. Laminated Safety Glass

Laminated glass is two or more sheets of glass bonded together with a plastic interlayer (usually PVB). If it breaks, the fragments stick to the interlayer and remain largely intact, helping prevent dangerous pieces from falling into the shower area. Stevenage Glass

Laminated glass is particularly useful when privacy, sound insulation, or extra protection is required, though it is less common than toughened glass for standard shower screens.

Common Types of Glass Shower Screens

Shower screen design goes beyond just glass type — how the panels are configured affects space, cost, and usability.

1. Frameless Shower Screens

- Minimal hardware

- Clean, modern look

- Typically thicker glass (8–10 mm or more)

- Makes small bathrooms feel more spacious

Frameless designs are usually installed with discreet channels, hinges, or clamps for a seamless appearance.

2. Framed Shower Screens

- Glass set inside a metal frame (usually aluminium)

- Often slightly more economical

- Can be ideal for smaller bathrooms

Framed screens are typically easier and faster to install but offer slightly more visible structure.

3. Semi-Frameless Shower Screens

- A hybrid with minimal framing around select edges

- Offers balance between cost and aesthetics

4. Walk-In and Wetroom Panels

- Large fixed panels without doors

- Modern and accessible

- Often use thicker glass (8–12 mm) for rigidity Showers To You

Glass Thickness and Its Importance

Choosing the right thickness depends on screen style and design:

Typical Thickness Range

- 6 mm – 8 mm: Common for standard screens

- 8 mm – 10 mm: Favoured for frameless and walk-in designs

- 10 mm+: Premium large panels or wetrooms (requiring more strength) Showers To You

Thicker glass:

- Feels more substantial

- Is less likely to flex

- Requires heavier hardware and fixings

A good rule of thumb from UK installers is:

For frameless or large shower screens, 8 mm or above offers better structural performance and longevity. Glass Helper

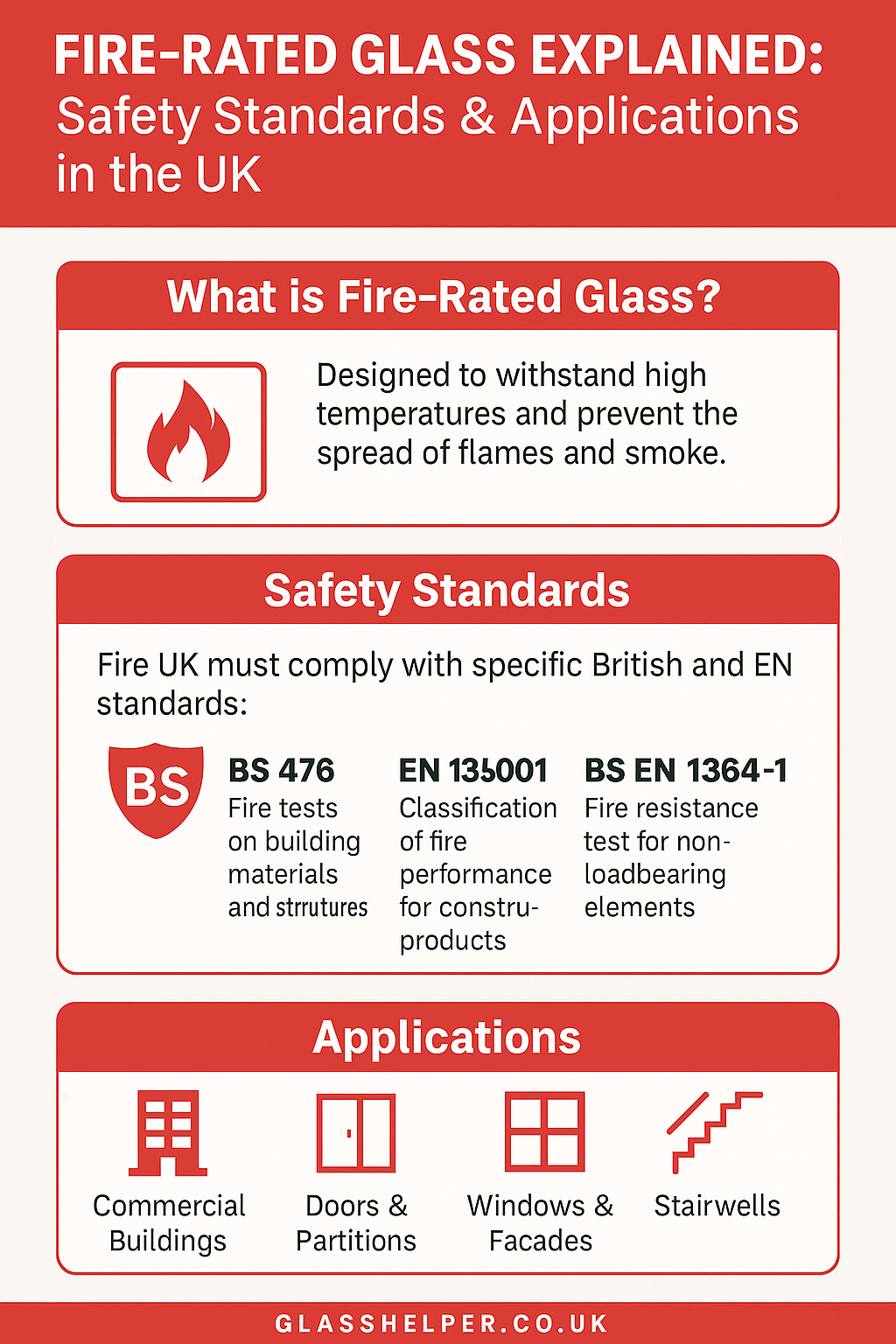

Safety Standards and Regulations in the UK

Safety isn’t an option — it’s a legal requirement.

In the UK, building regulations and British Standards require that all shower glass within reach and height zones must be safety glass. This includes:

- Shower doors

- Fixed panels

- Glass screens

This is supported by the UK’s general safety glazing rules:

- All glazed elements within 800 mm of floor level should be safety glass. Glass Helper

Key Standards

- BS EN 12150 – Toughened safety glass

- BS EN 14449 – Laminated safety glass

These standards ensure the glass is heat-treated, impact tested, and suitable for everyday bathroom use. abc Glass Processing

Building Regulations

UK Building Regulations (e.g., Part K and related guidance) treat bathrooms as where the risk of slipping and glass breakage is significant and therefore safety glass is required. Glass Helper

Always confirm that your installer or supplier can confirm compliance to these standards — ideally with visible marks on the glass or documentation.

Design and Configuration Considerations

Glass shower screens come in a wide range of styles and shapes. To choose the right one, consider:

1. Bathroom Layout

- Walk-in panels work well in spacious bathrooms

- Pivot or sliding doors suit tight spaces

2. Aesthetic Preferences

Clear glass makes a bathroom feel more open; frosted or patterned glass adds privacy and style.

3. Maintenance

Water stains and limescale build-up are common in bathrooms. Some glass finishes include:

- Water-repellent coatings

- Easy-clean surfaces

These options help prolong pristine clarity with minimal effort.

4. Privacy vs. Light

Low-iron or ultra-clear glass maximises light; frosted or textured options offer privacy without blocking light entirely.

Installation and Practical Tips

Professional Installation Is Essential

Glass shower screens may seem simple, but they require:

- Precise measurement

- Correct sealing

- Strong fixings to walls or floors

Improper installation can lead to:

- Leaks

- Glass stress and cracking

- Doors that don’t close correctly

Hardware and Support

Quality hinges, channels, and seals not only improve look but also longevity. Heavy-duty hardware is especially important for thicker or frameless panels.

For detailed guidance on glass installation standards across bathroom applications — including door safety and glazing rules — this helpful homeowner’s guide expands on UK requirements:

👉 UK building regs affecting glass in bathrooms and other areas — https://www.glasshelper.co.uk/uk-building-regs-for-glass-a-simple-homeowners-guide-2025-update/

Cleaning and Maintenance

Glass shower screens are easy to keep looking fresh if you follow a few simple steps:

- Wipe dry after each shower

- Use non-abrasive glass cleaner

- Avoid harsh acids that can damage seals and coatings

Maintaining hardware (like hinges and seals) for smooth operation is also key to long-lasting performance.

FAQs About Glass Shower Screens

Do glass shower screens shatter easily?

No — when specified as safety glass (toughened or laminated), they are designed to withstand daily impact and break into less dangerous fragments if they do break. ToughGlaze

Can I fit a shower screen myself?

Not recommended. Professional installation ensures correct sealing, alignment, and compliance with building standards.

Should a shower screen extend all the way to the ceiling?

This is a design choice. Full-height screens reduce steam and water escape but may be less accessible in smaller bathrooms.

Conclusion

Glass shower screens blend form and function — letting light flow through your bathroom while containing water and maintaining safety. Key decisions include:

- Choosing the right type of glass

- Meeting UK safety standards

- Designing for your bathroom layout and maintenance preferences

For a full breakdown of styles, materials, pricing, and design ideas for shower screens, check out this dedicated resource:

👉 Glass shower screens inspiration and options — https://www.glasshelp.co.uk/glass-shower-screens/